Ford 390 FE Engine Overhaul

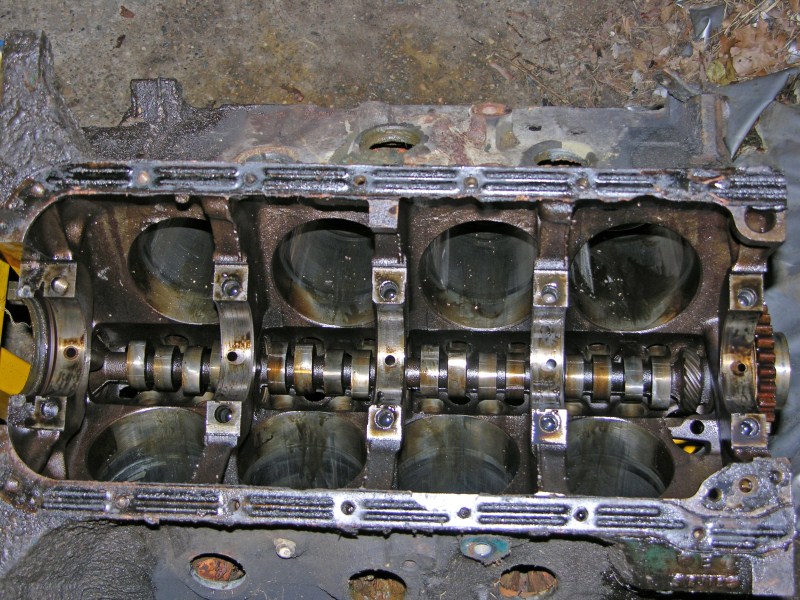

CAM REMOVAL

CLICK HERE

to return to Home Page

The cam can only come

out after the lifters are out. In order to get the lifters out, the Valve

Covers, Rocker Arm Shafts, Pushrods, Distributor and Intake Manifold must be removed.

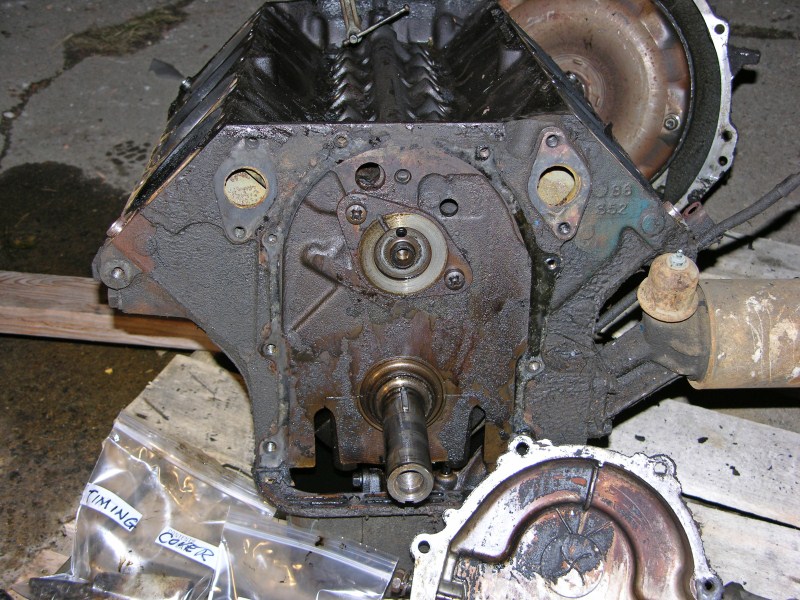

Since pushrods go through holes in the Intake Manifold, the sequence needs to

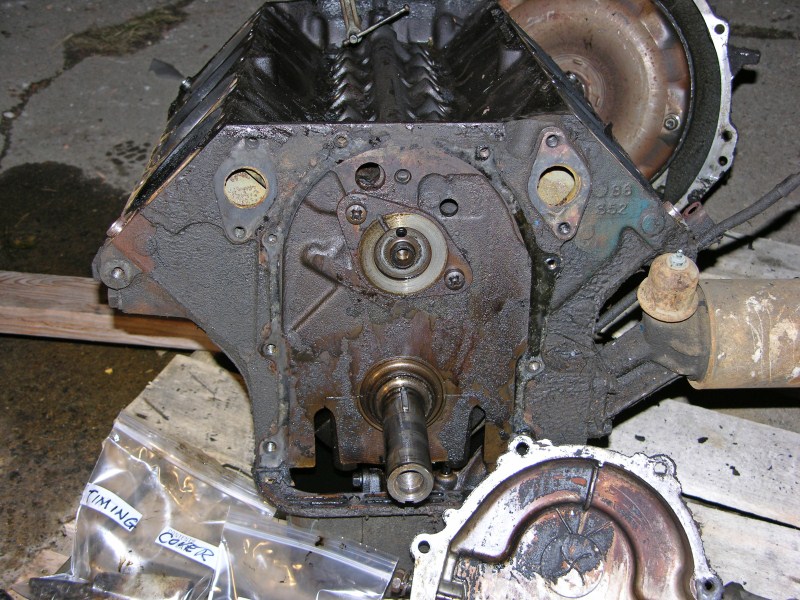

be followed in this order. Then, the Damper Pulley, Sleeve, Water Pump, Timing cover

(with Fuel Pump), and Timing Set must be removed. (See

TIMING SET REMOVAL.)

At this point, the cam may be

pulled out and no special tools are needed if the Crankshaft is out.

These cams are heavy, sharp and expensive. With the Crank out, you

can get your hands in there to prevent galling your Cam Bearings.

#1

#1

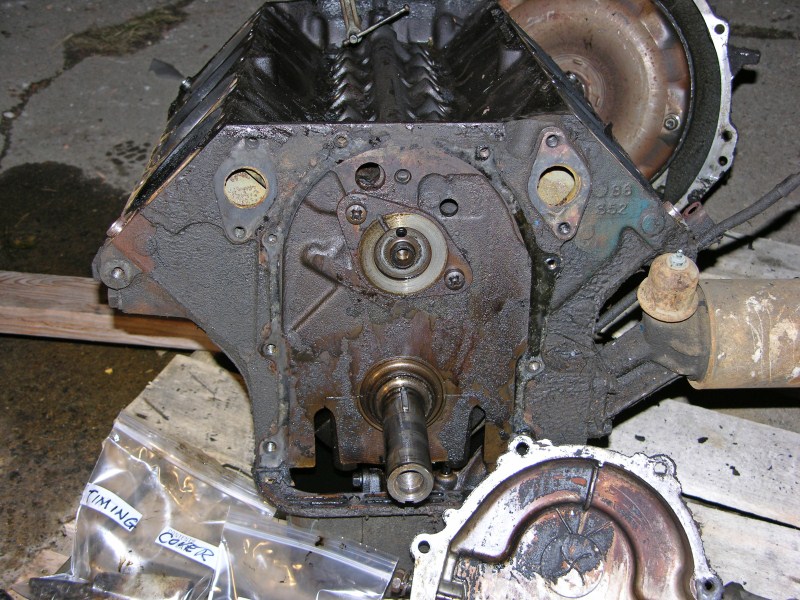

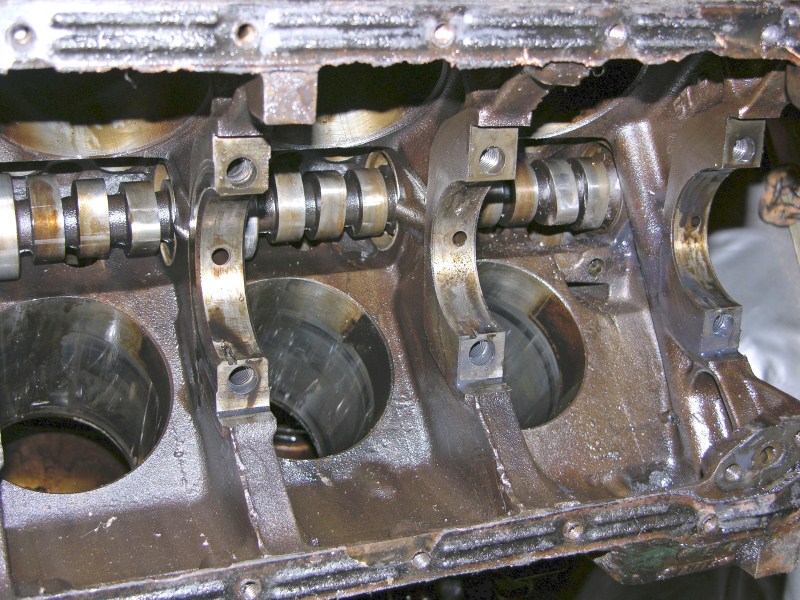

Remove the Cam Thrust Plate and all 16 lifters. If the lifters

don't slide out easily work them up and down. Eventually the

varnish

will give out then the lifters will come.

#2

#2

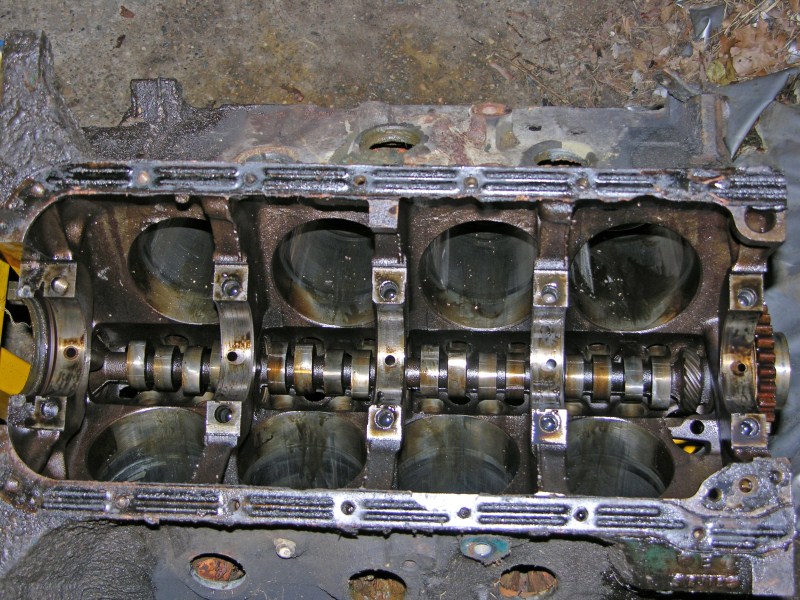

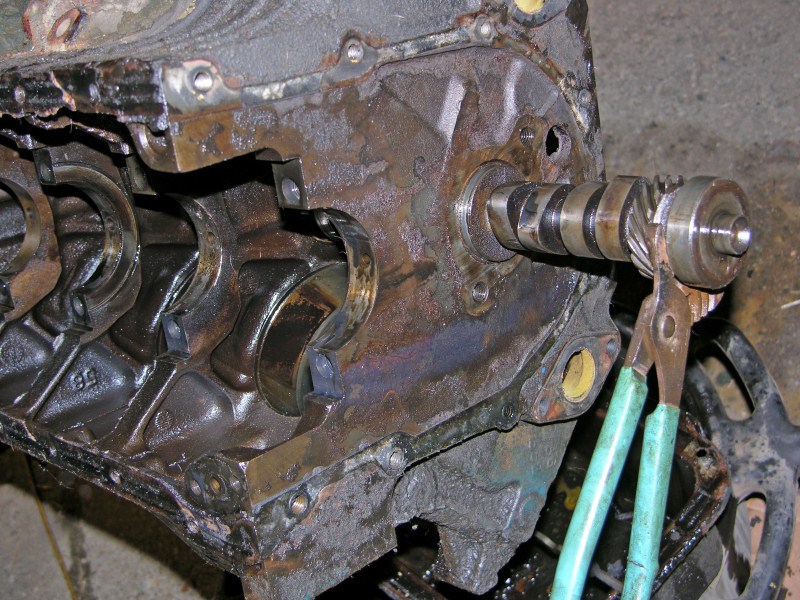

There are two ways to remove the cam. The very easiest way is with

the crank removed. Why? Because the cam is heavy, very long,

and the lobes are sharp enough to cut your hands. Speed shops sell

extensions you can bolt onto your cam nose, so you can use it as a

lever. Since I am doing a major overhaul, I will remove the

crankshaft first, and make life easy on myself.

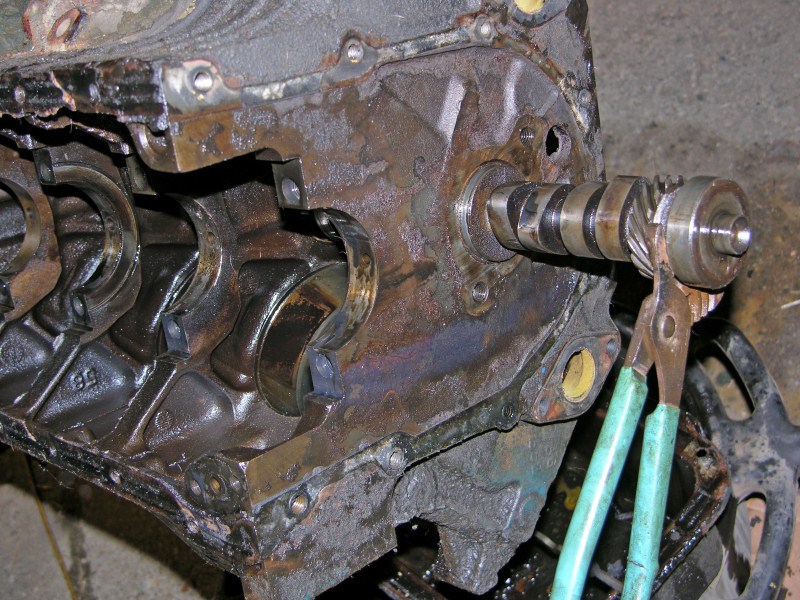

#3

#3

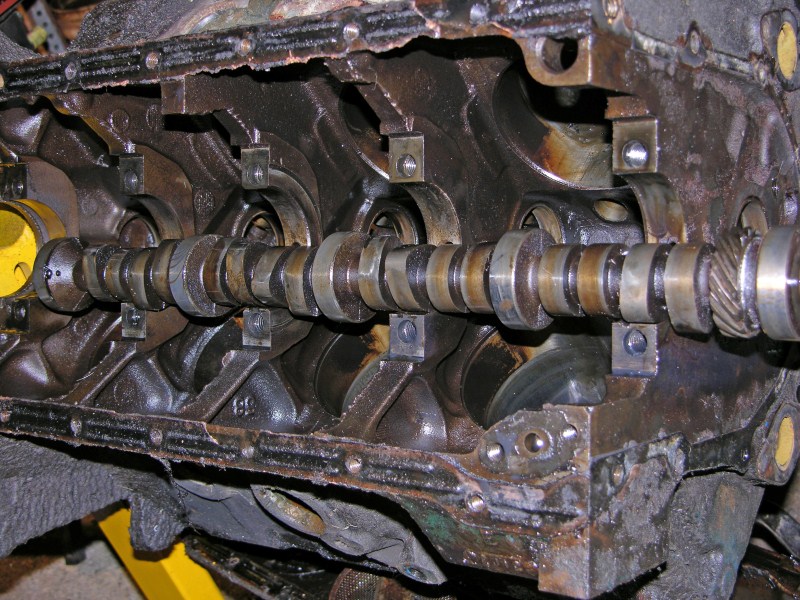

Twist the cam as you pull it out. If it helps, leave the

thrust plate off but put the sprocket back

on and twist out. If the cam still gives you problems, tap the

cam from inside the block in a forward motion just behind the

distributor gear.

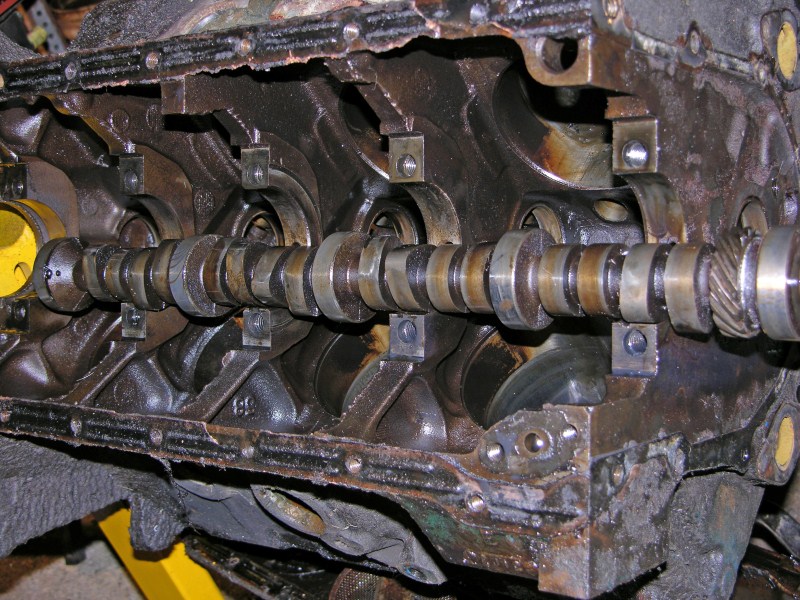

#4

#4

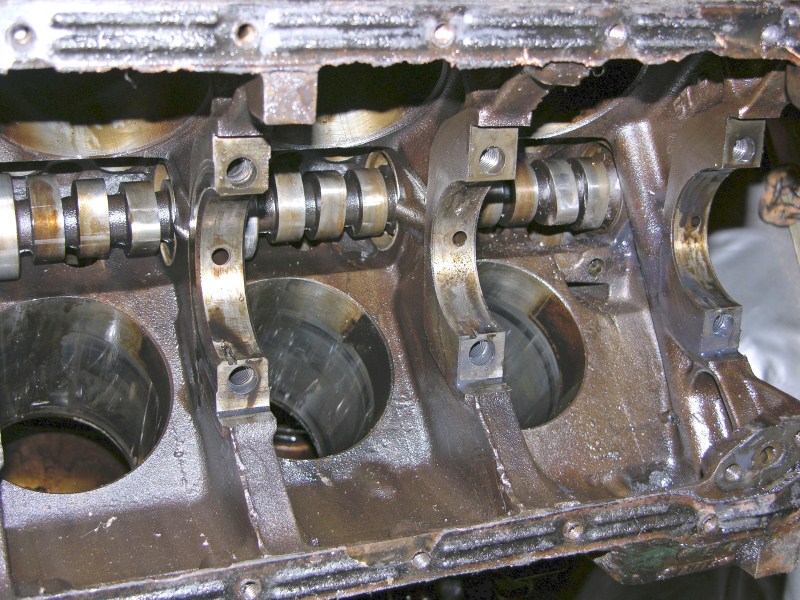

Eventually it will come out. As it does, carefully 'fish' it

out and try not to tear up the cam bearings.

#5

#5

#6

#6

This Cam was hard coming, so I use Channellocks to twist while I

stabilized the cam inside the block.

#7

#7

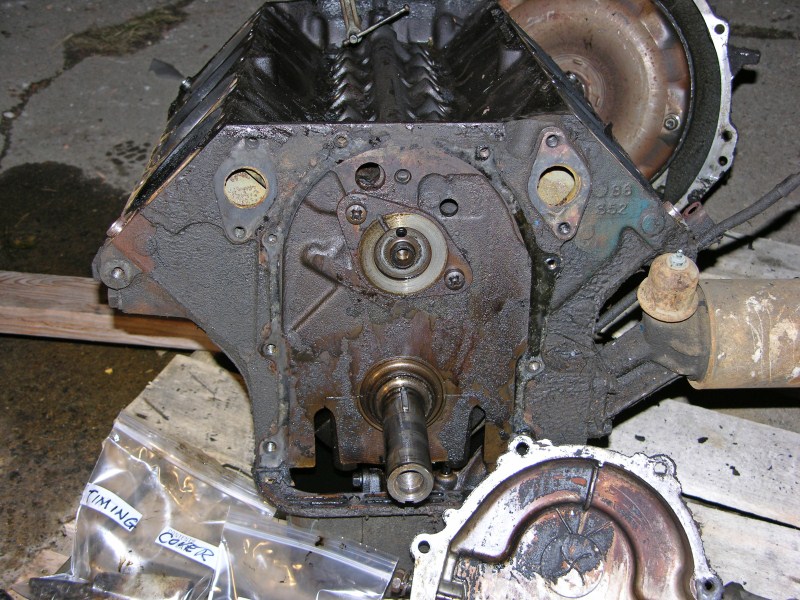

Finally out. Cams should install and remove very easily.

This block is going to the machinist for a good align bore.

CLICK HERE

to return to Home Page

Top of Page>

#1

#1 #2

#2 #3

#3 #4

#4 #5

#5 #6

#6 #7

#7