Ford 390 FE Engine Overhaul

WATER PUMP & TIMING SET REMOVAL

BACK TO HOME PAGE

Whether you are shooting for an overhaul

or simply changing your timing chain, this procedure is the same.

The only 'fancy' tool you will need is a puller for the damper pulley.

I made my own for under a couple bucks. The rest is rather easy;

use the crankshaft bolt to draw the damper pulley back up when you're

done. Let's get started...

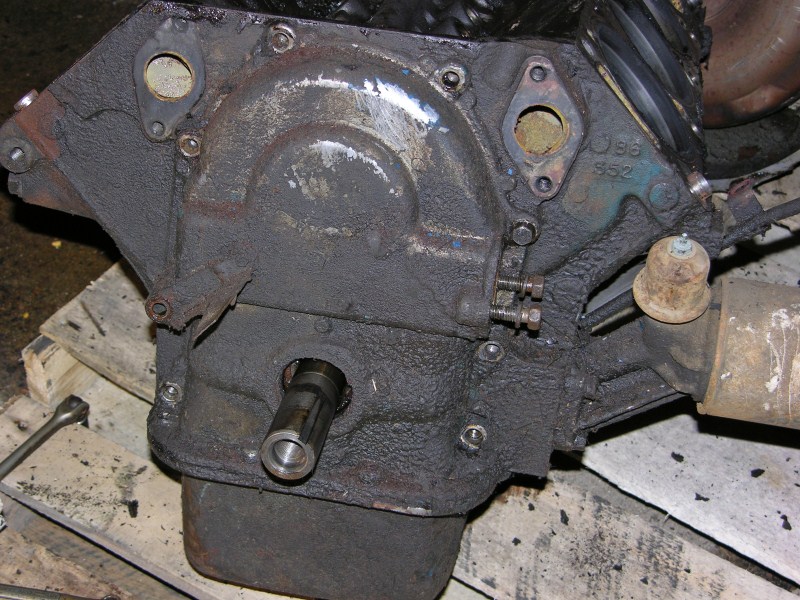

#1

#1

Remove belts, brackets and everything hanging from them.

We call this the engine's, FINAL DRESS. Next, remove (4) bolts

that hold the water pump on, with a 9/16" wrench. Remove the

fuel pump and filter assembly.

Since I'm here, I also loosened some of the Timing Cover bolts.

Most of them need a 1/2" wrench except for the very bottom-front

three bolts.

They use a 9/16".

The oil pan lip in front is bolted from the bottom with four bolts.

#2

#2

There are the

three bolts, just under the bottom Water Pump bolt.

If you have a good array of tools, you can get around the oil

filter. If not, take the oil filter bolts off, then the fuel

pump bolts are a straight shot.

#3

#3

This is the bolt everybody dreads, but it really isn't bad IF you use proper tools. There are no surprises or left-hand

threads. The trick is to stop the crank from turning. If the engine is in the car,

just put it in gear and hold the brake on. On the automatics, I pull the inspection plate off and use a screwdriver in the flex plate teeth.

Here with the engine out of the car, I'm using a "C" clamp

on the flex plate. For the Damper Pulley bolt, I use a 1/2"-drive, 1" hex socket. I don't keep a lot of unnecessary tools, so my torque wrench doubles as a long breaker bar.

#4

#4

There's my secret.

#5

#5

#6

#6

The 'C' clamp rests on the block and

easily holds the crank solid.

#7

#7

With a little muscle

and serious leverage, this bolt came right off. It's a regular

national fine thread.

#8

#8

Now we need a

puller, but where do we attach it?

#9

#9

Remove the three

pulley screws with a 9/16" socket, and use these holes for your

puller. There is no need to separate the damper pulley from

the sheave, but you can (I didn't).

#10

#10

Remove the big washer from the Crank bolt and screw it back in, about

six turns.

I didn't have a puller, so I quickly fabricated the one you see

(from: four nuts, three strips of steel,

and a center bolt). It took me ten minutes.

There is a 1/2" nut tack welded

beneath the center 'jack screw'. The

puller's

jack screw then pushes the Crank bolt in, while the three

slot-head screws pull the pulley out. The three slotted screws

are very soft 'junk' I had laying around.

#11

#11

As you turn the jack screw in, the damper pulls off the crankshaft.

Let's see behind it...

#12

#12

Yep, it's coming...

#13

#13

After removing the puller, you can see witness marks on the

Crankshaft bolt head (from the jack screw). Don't forget to replace the three

grade 8 pulley

bolts.

#14

#14

Now it's off, and the seal sleeve is next. Remove the crank

bolt, put the large washer back on, label and bag it. This is

an important bolt you really don't want to replace because they are

rare and not many places sell new ones.

#15

#15

I rotated the crank

so the key faces up.

#16

#16

I can feel the sleeve

is loose... The only thing holding it back from sliding off is

that key.

#17

#17

A simple screwdriver pries it out and the sleeve comes sliding out

by hand. SAVE THE KEY. I've heard discussion about how hard this sleeve is

to remove. Once the key was removed it slid off by hand.

#18

#18

Why is this part necessary? GM engines don't have one.

It became evident when I re-assembled the timing cover. The

oil pan has a (partial) gasket on the front lip and the big

'horseshoe' gasket goes against the block. Without the sleeve,

it's easy to lift the cover up, and drop it down on the oil pan.

This keeps the gaskets neatly in place before bolting it up.

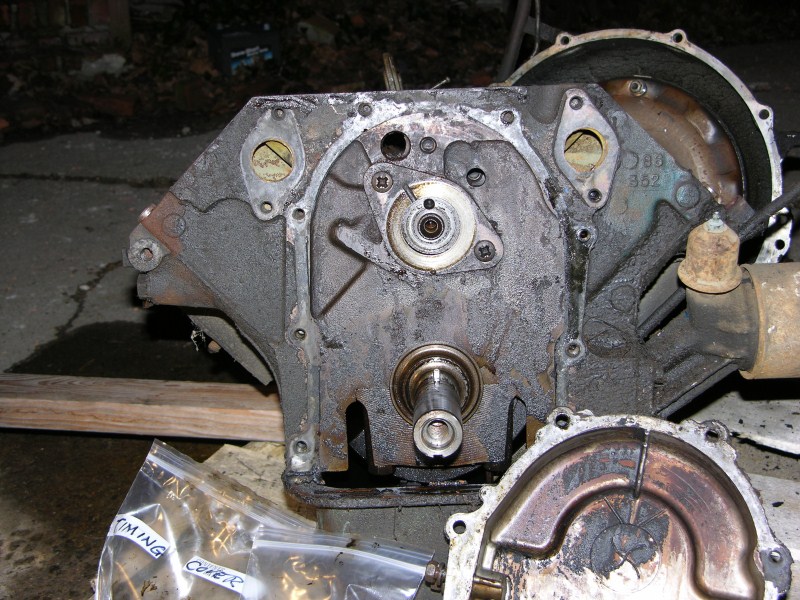

#19

#19

Now, remove the Fuel Pump and all the Timing Cover bolts, especially

the four on the bottom (going through the oil pan). NO

FORCING, this cover comes of easily once all the bolts are removed.

Just break the gasket seal and it's off.

#20

#20

One more bolt and it's off.

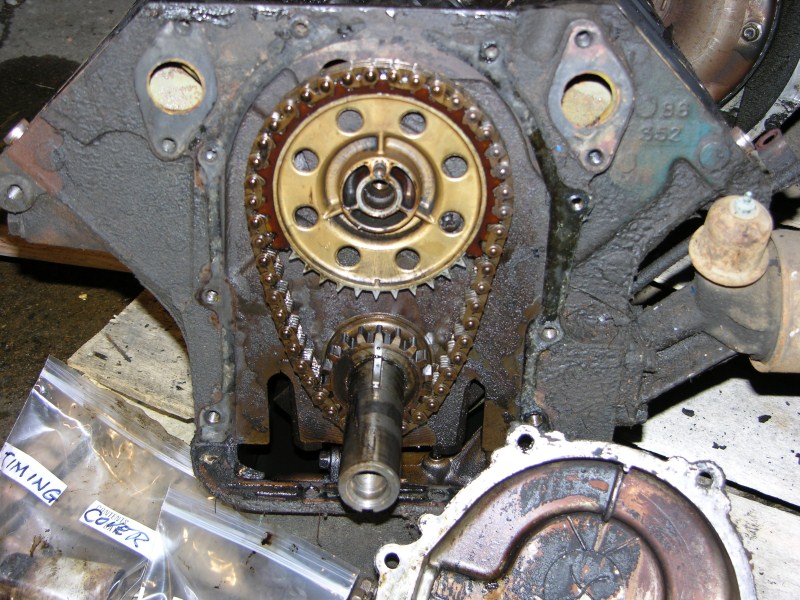

#21

#21

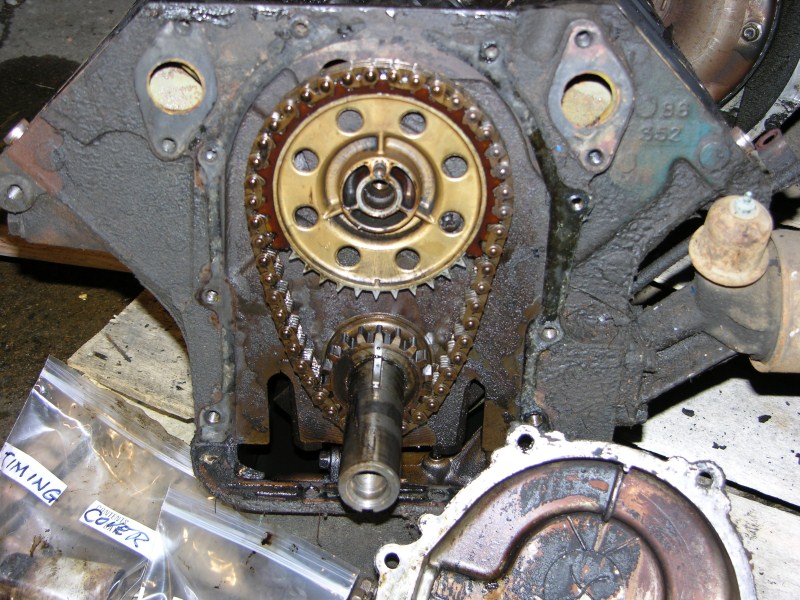

This is an "Ah, HA!" moment for me. Look close.

#22

#22

Look even closer... Half the nylon cam sprocket teeth are MISSING!

Back in the '70's all the big-3 engine plants used Delrin nylon cam

sprockets. They were supposed to reduce noise and wear longer.

The problem was, they would typically get brittle and self destruct from the engine

heat. If timing jumps and valves are open far enough for the pistons to collide

with them, it's a major catastrophe. This engine was shakin'

dice.

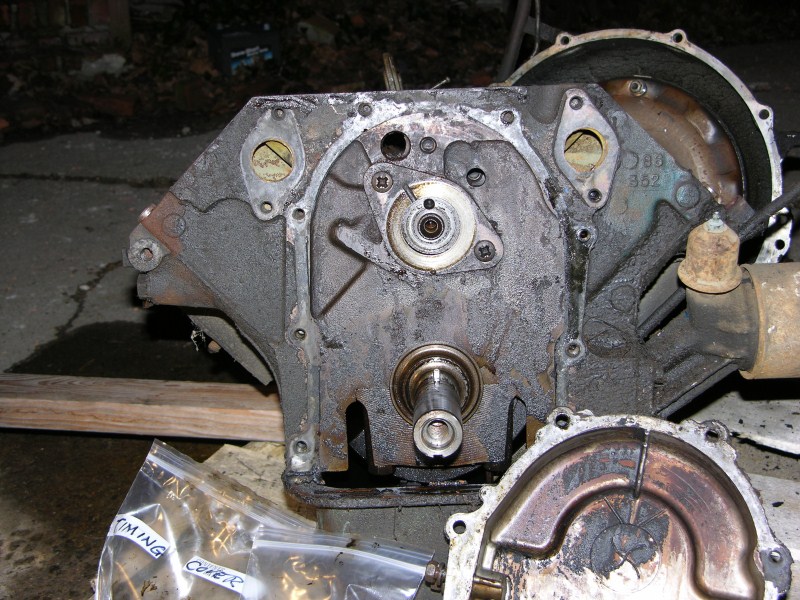

#23

#23

Pull off the oil slinger on the crank, loosen the Cam bolt, and pull

the sprockets off. No puller is necessary. I used two

screwdrivers behind the cam sprocket. Label and bag the parts.

Do not throw any old parts away until your engine is done.

#24

#24

I'm amazed the timing marks still match.

#24

#24

1/3 of the nylon is missing. I'm replacing with a True Roller

Timing Set, made with iron and steel, so this will never happen

again.

#26

#26

To remove the Cam, go to "CAM REMOVAL" on the Home Page.

Top of

Page

BACK TO HOME PAGE

#1

#1 #2

#2

#4

#4

#17

#17 #18

#18 #19

#19 #20

#20 #21

#21 #22

#22 #23

#23 #24

#24

#26

#26