|

From: Tony & Liz

May 11, 2011

Subject: Wiring changes from old 1959 Thunderbird

generator system to Ford 3G Alternator

I have tried to change the old wiring diagram, to explain it a

little.

I have not wired under the hood yet .

My questions are

1. The terminal from the "I" circuit; do I just wire it

straight to the Generator light, or do I need to couple it

to the "I" side of the starter switch on the guard?

2. If I leave the large power supply wire to the removed voltage

regulator to power the horn relay is this safe?

3. Where do i pick up the power supply for my electric choke

(needs to be 12 volts and no less)?

ANSWERS: 1. This wire is very important! Without it,

your alternator will not sense your key is on and will not

|

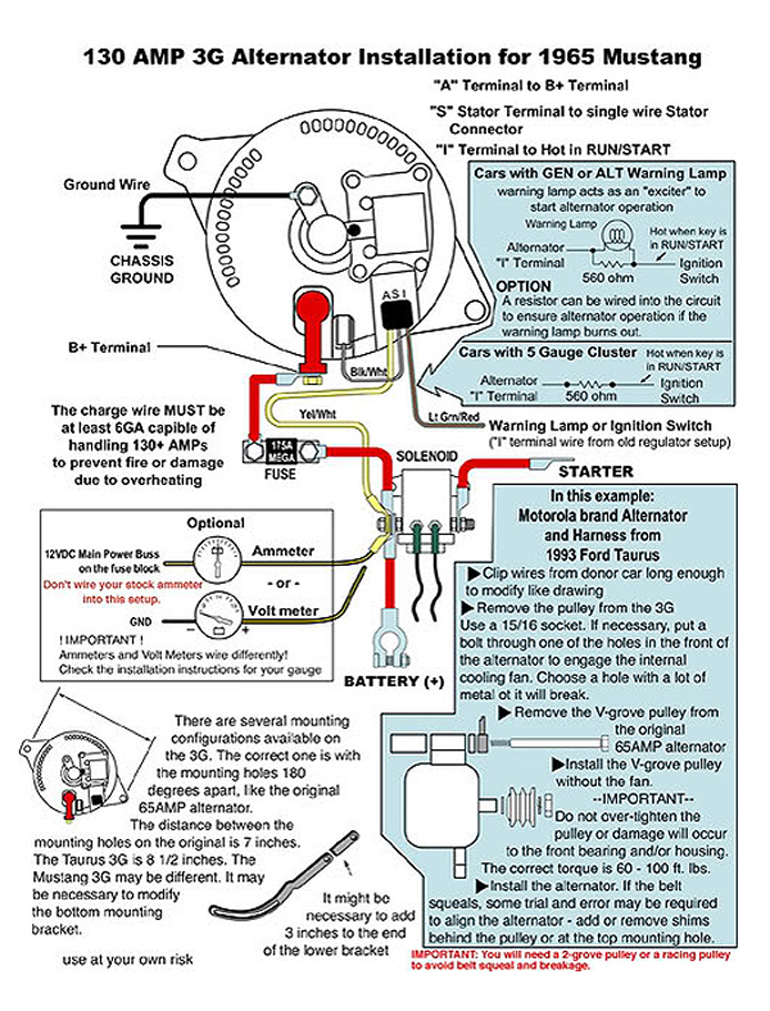

(Click on the images below for a printable size.)

#1

#1

The above diagram explains the need for #6-AWG copper

stranded wire to carry the high current, and it

includes a fuse. The fuse is VERY important.

If one of your diodes ever shorts inside the new alternator, your

battery will unload as much current to ground as possible in the shortest

amount of time. This burns

your wires

and

leaves a dead battery (or just a blown fuse).

As shown in the drawing below:

See the yellow/white wire labeled "A"? A more simple

attachment would be to connect it to "B+" on the Alternator.

If you can't use a two-groove pulley, a larger diameter

single groove pulley will work. It has more surface area for

the 'V' belt to grab and the larger diameter gives a better 'lever', making it

easier to turn. The downside is your

engine needs to run a bit faster than idle, to produce current.

#2

#2

Back to Squarebirds.org