Ford 390 FE Engine Overhaul

TEARDOWN LOWER END 3

CLICK HERE

to return to Home Page

This site deals with General Engine overview. Subsets will address the top, bottom,

front, and rear portions of this teardown. That will make future reference for finding

specific tasks much easier.

#1

#1

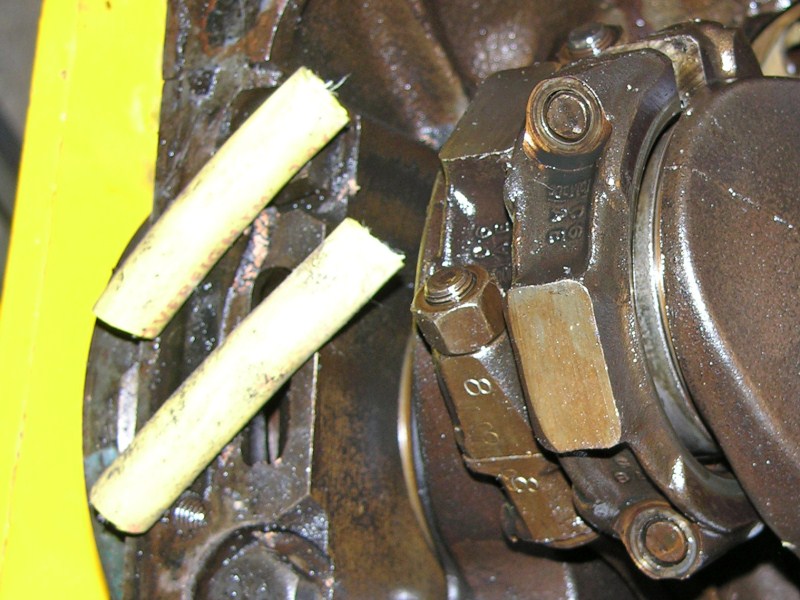

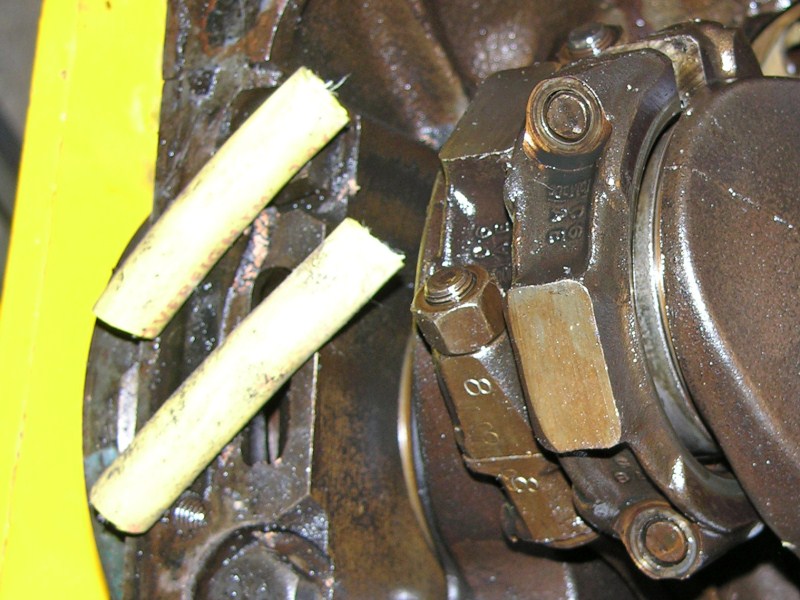

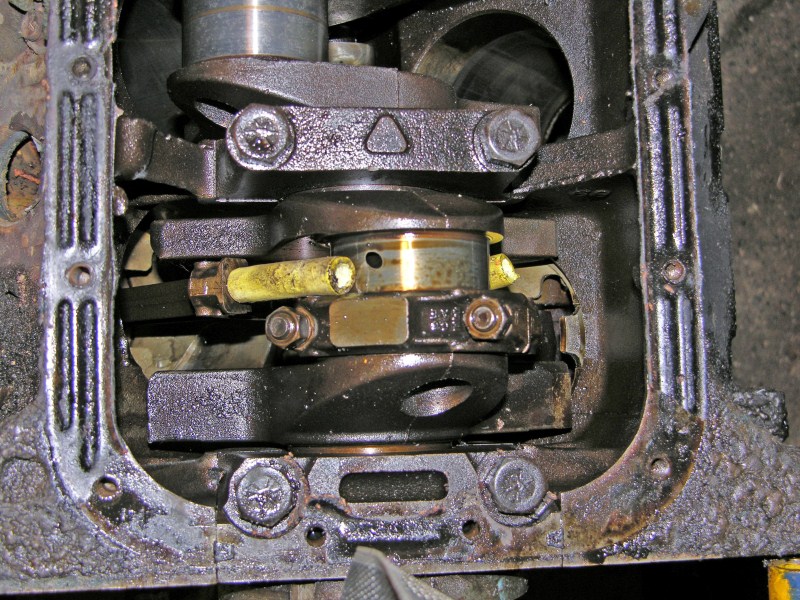

Rotate the crank until the connecting rod cap comes up to the top.

Remove the cap nuts. Tap the piston loose. Notice those

two yellow tubes on the left. I use them to protect the

crankshaft. The smallest nick in

the crank pin will wipe out a new bearing. So, I slip covers over

the con rod bolts to protect my work. You can use anything

that's soft, but thin. I pulled these off of extension cord I

had.

If you happen to nick the crank, stone out the flaw, immediately.

#2

#2

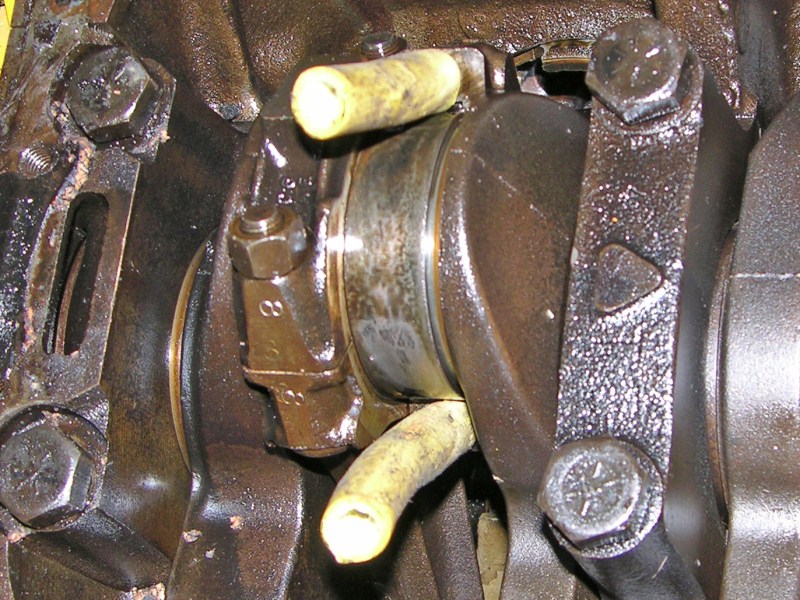

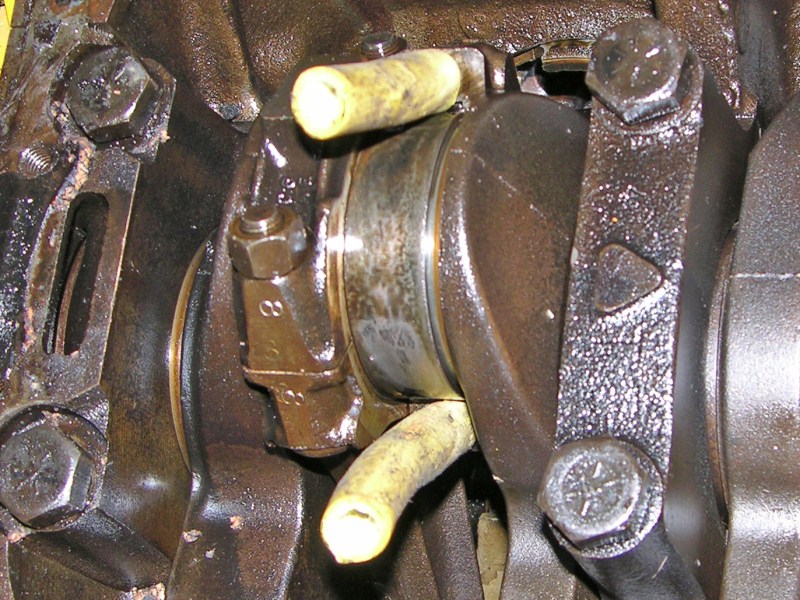

It's just electrical cord covering but for this use, a great

tool.

#3

#3

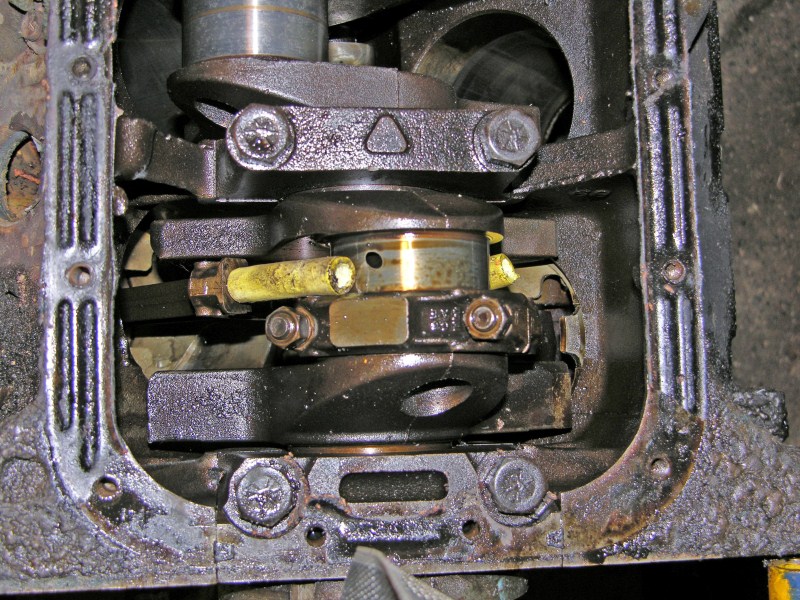

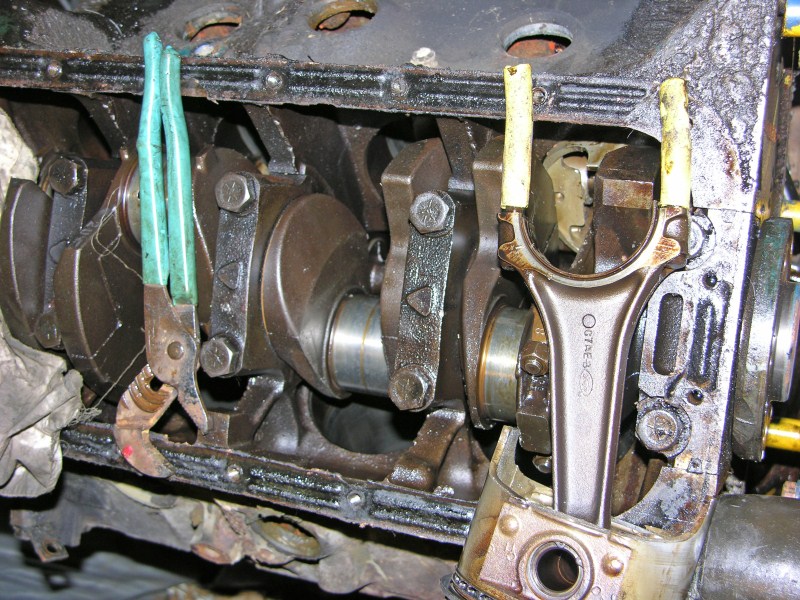

The cap is off but the

bearing stayed on the crank... ok.

#4

#4

Push the covering over the connecting rod bolts...

#5

#5

Now it's safe to pound the old piston out using a rubber

mallet or wood.

#6

Put your hand under the piston to catch it.

#7

#7

This piston is on its way down. Assembly follows the

exact opposite procedure.

#8

#8

Now pull the rubber sleeves off and get them ready for the next

piston.

#9

#9

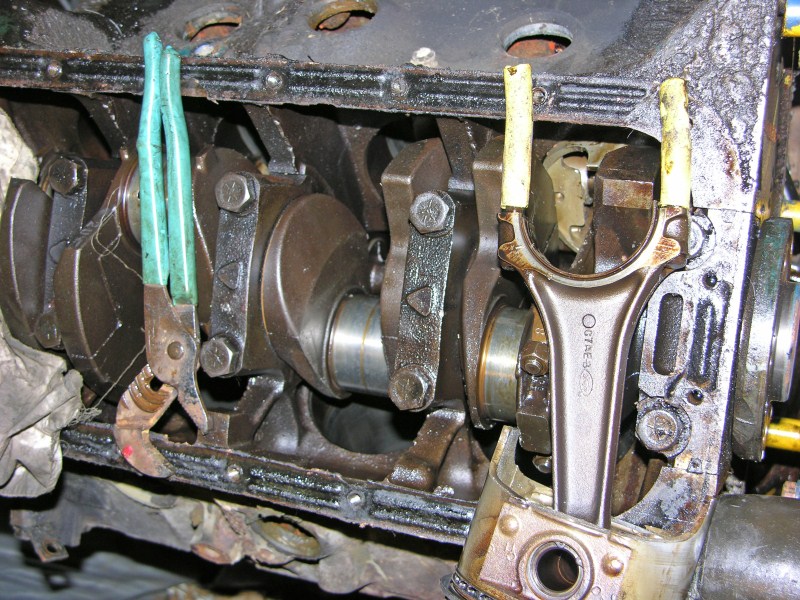

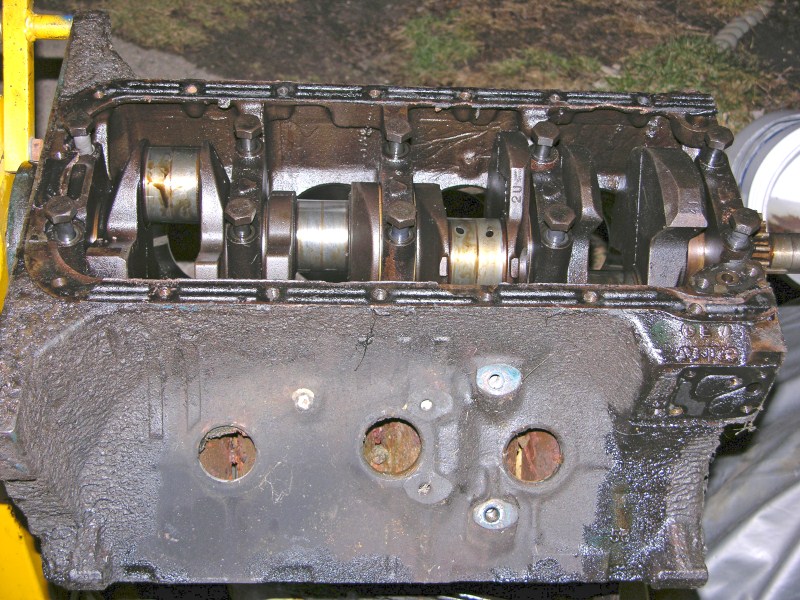

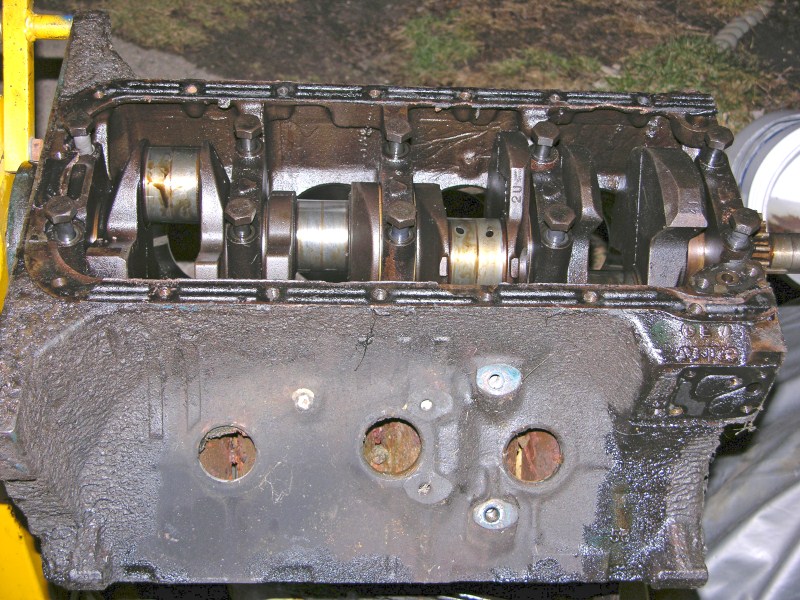

When all the pistons are out, loosen the main journal bolts

and pull each cap off.

#10

#10

Set the caps off to the side. This Crankshaft is ready

to lift out.

#11

#11

Each of these caps is stamped for position. I want to

keep them that way because the machine shop will align bore the

block. It's important to keep everything in order.

#12

#12

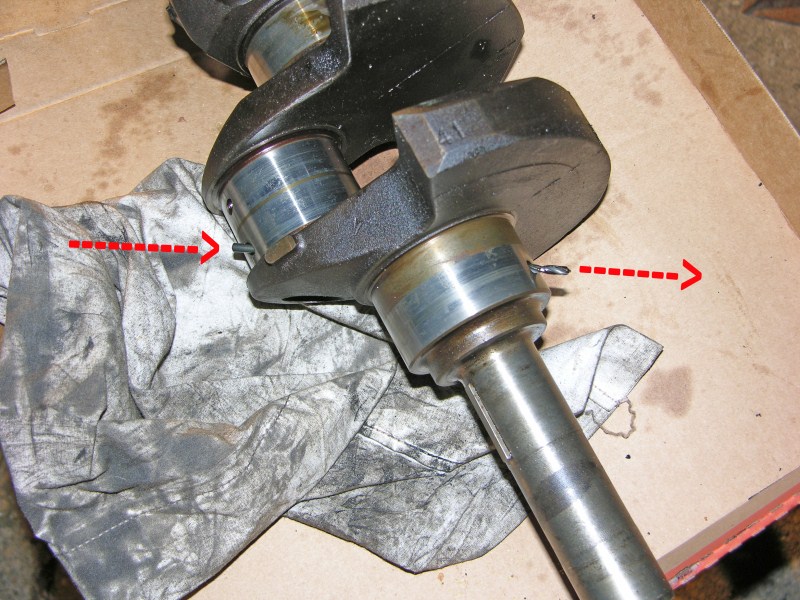

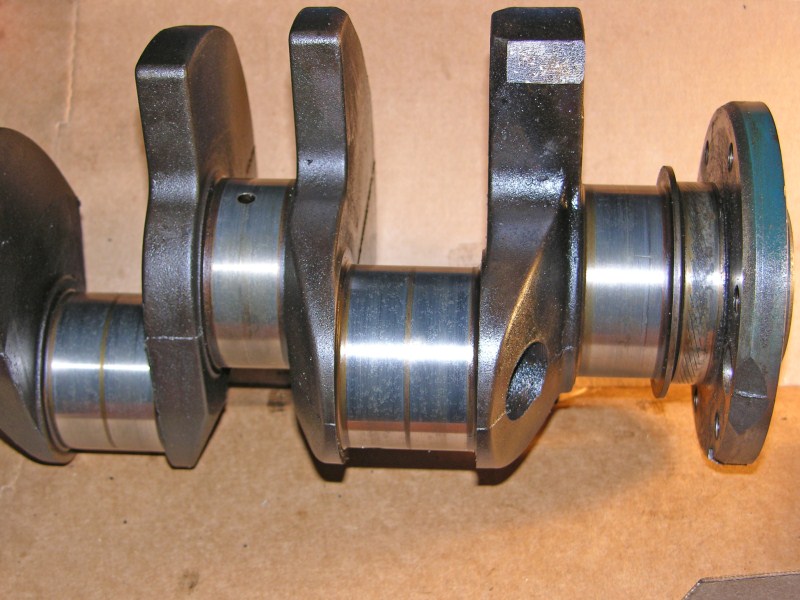

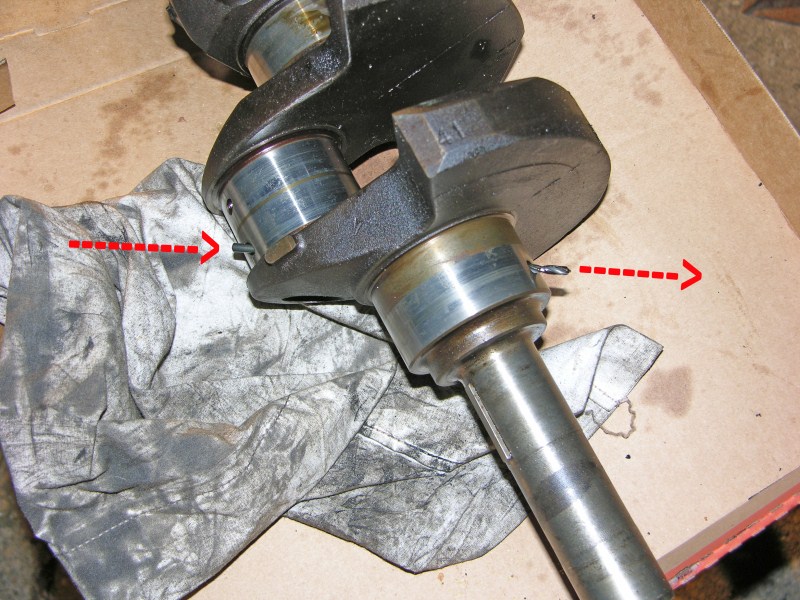

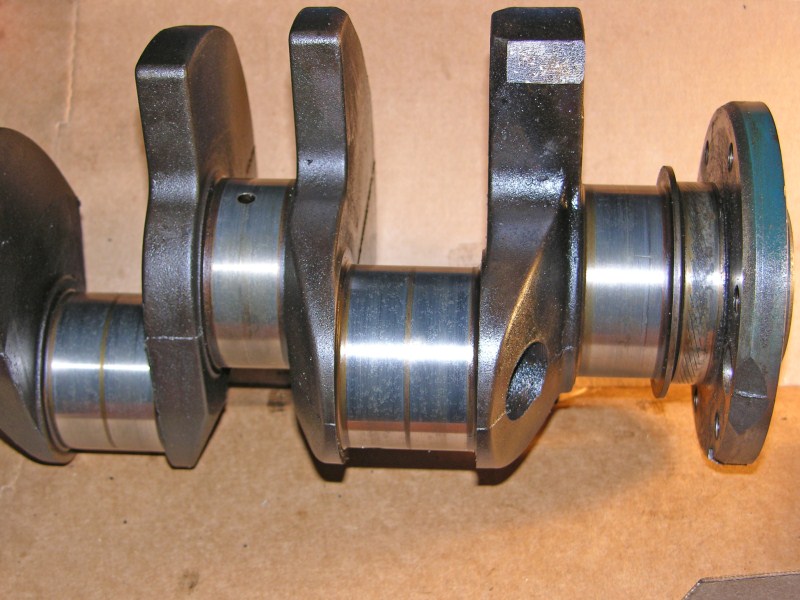

This Crankshaft is a 2U, one of Ford's strongest, and it

looks beautiful.

#13

#13

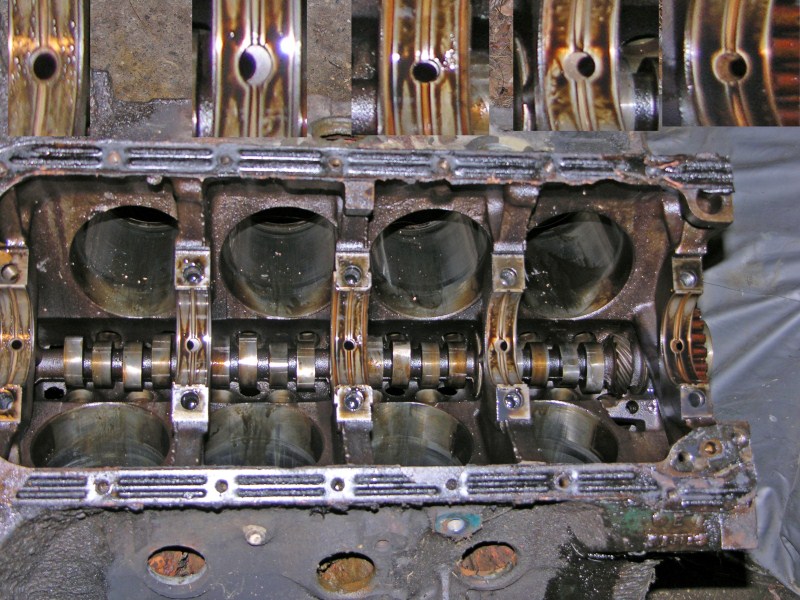

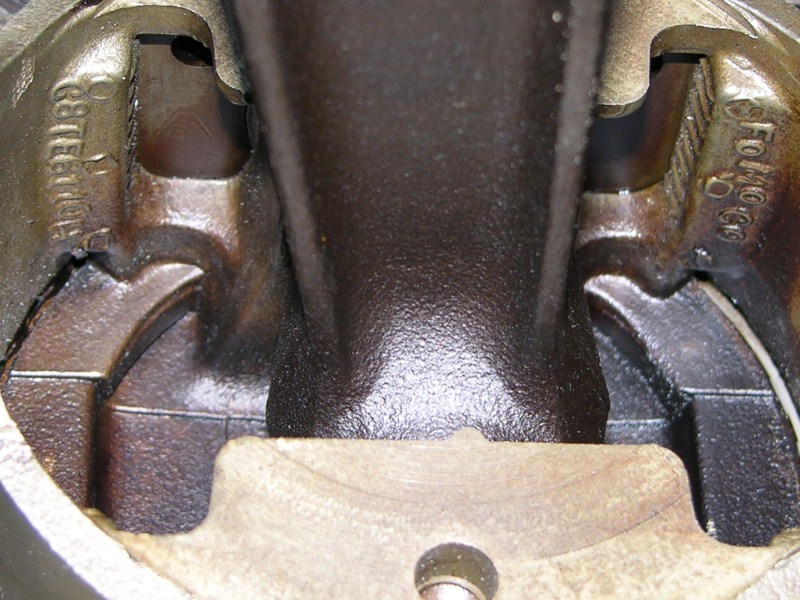

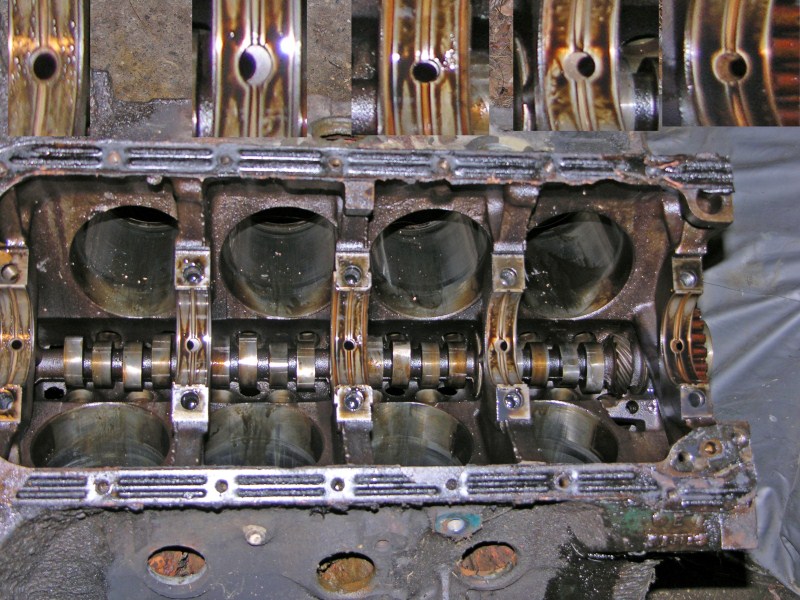

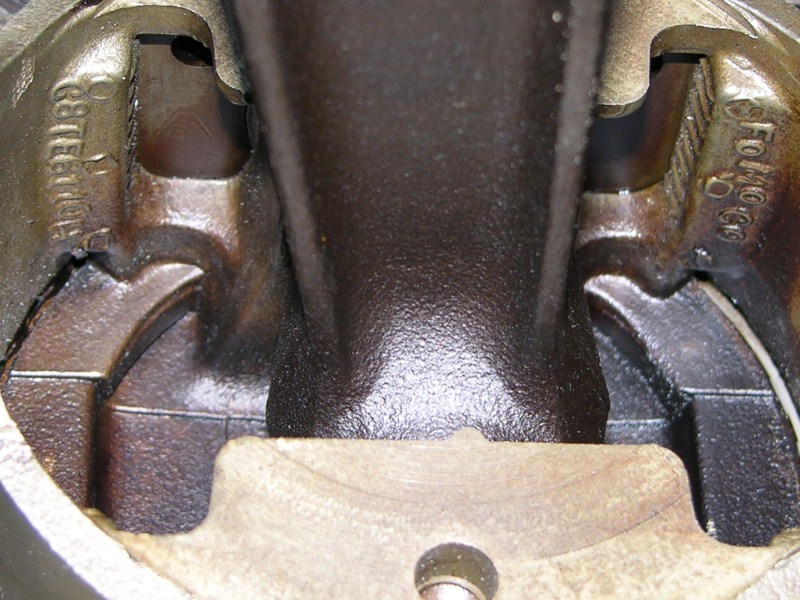

I took this picture to show the bearing oil holes and how

they are misaligned by the cradle oil holes. (See the

five close-up insets at the top of this picture.) The

machine shop will straighten this out.

Also notice, I left the cam to be removed last. Once the

crankshaft is out, I have access to the Camshaft with full

control using both hands inside and outside of the block.

#14

#14

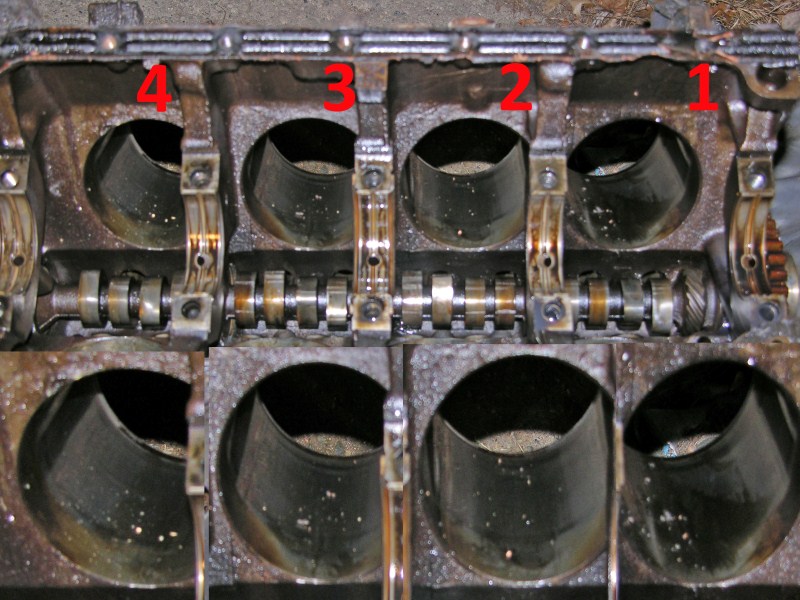

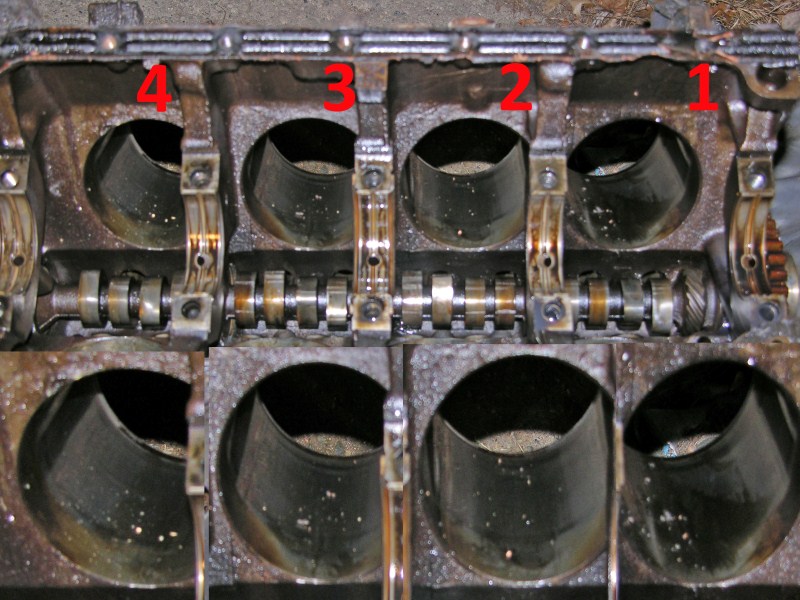

Even though this block will be bored, it's noteworthy to show

the cylinders 'before'. The junk in there is gasket

material and oil, but no scoring.

#15

#15

... and the LH cylinders.

#16

#16

The engine plant uses very long drill bits to make these oil

holes. I check and clean every oil hole.

#17

#17

The main and pin bearing surfaces look great.

#18

#18

The inset shows "2U" identification... clearly a

car or light truck

crankshaft.

#19

#19

Original bore is 4.050". This block proves to be

original in every way.

#20

#20

This piston bearing is typical of all eight. They are worn out from

low-rpm but high torque.

#21

#21

The inside of this piston reads: "C8TE6110H" (1968 Truck

Engine...) on the left, and "FoMoCo" on the right. It's

heavy duty and high quality, with a full-floating wrist pin held

in by snap rings.

#22

#22

I pulled this ring off to measure the end gap. .040",

and the cylinders have hardly any ridge.

#23

#23

Remove six oil and water pipe plugs with an Allen wrench.

#24

#24

These four pipe plug holes surround the Camshaft Plug in the

back of the engine. Now, this block is absolutely bare and ready for the hot tank.

Back to top

CLICK HERE

to return to Home Page

#1

#1 #2

#2 #3

#3

#4

#4 #5

#5

#7

#7 #8

#8 #9

#9 #10

#10 #11

#11 #12

#12 #13

#13 #14

#14 #15

#15 #16

#16 #17

#17 #18

#18 #19

#19 #20

#20 #21

#21 #22

#22 #23

#23 #24

#24