Ford 390 FE Engine Overhaul

TEARDOWN

& REFURBISH ROCKER ARMS AND SHAFTS

BACK TO MAIN MENU

ROCKER ARM REMOVAL

& SHAFT CLEANING

#1

#1

Rocker shafts are the same for both sides but they have a top

and a bottom.

Notice the stands' bolts are not all the same. The 2nd bolt has a skinnier

diameter shaft.

Oil must go up the head and around the second stand's

bolt to enter the shaft. Do not mix up these bolts.

This was covered in OIL MODS.

#2

#2

#3

#3

Notice the notch on the

end of this OEM shaft. It only appears on one end. When properly

assembled,

the notch should be at the 5 O'clock orientation and

the rocker arm tips should face the left.

That ensures the shaft's oil holes are at the bottom.

#4

#4

Time to strip the rocker arms and stands off the shafts. Start

with the bolts and cotter pins.

Notice this end has no notch because it's the other end of the same shaft.

#5

#5

Rocker arms on each end have spring washers to ensure alignment to the valve.

Center rocker arms have

springs between them.

Every time a push rod relaxes, the shaft springs push the rocker arms back to it's

stand.

#6

#6

Slide all the rocker arms and stands off.

#7

#7

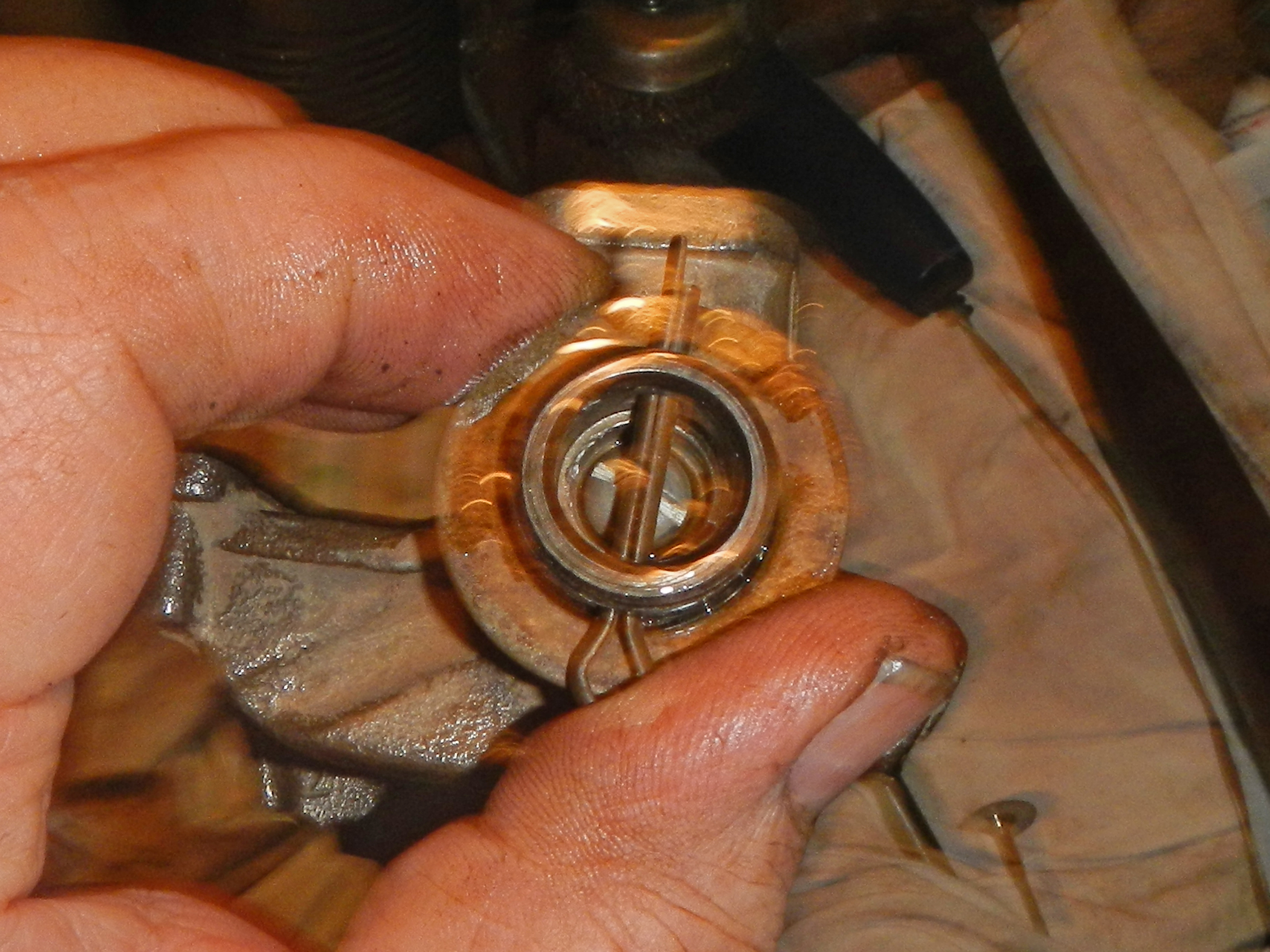

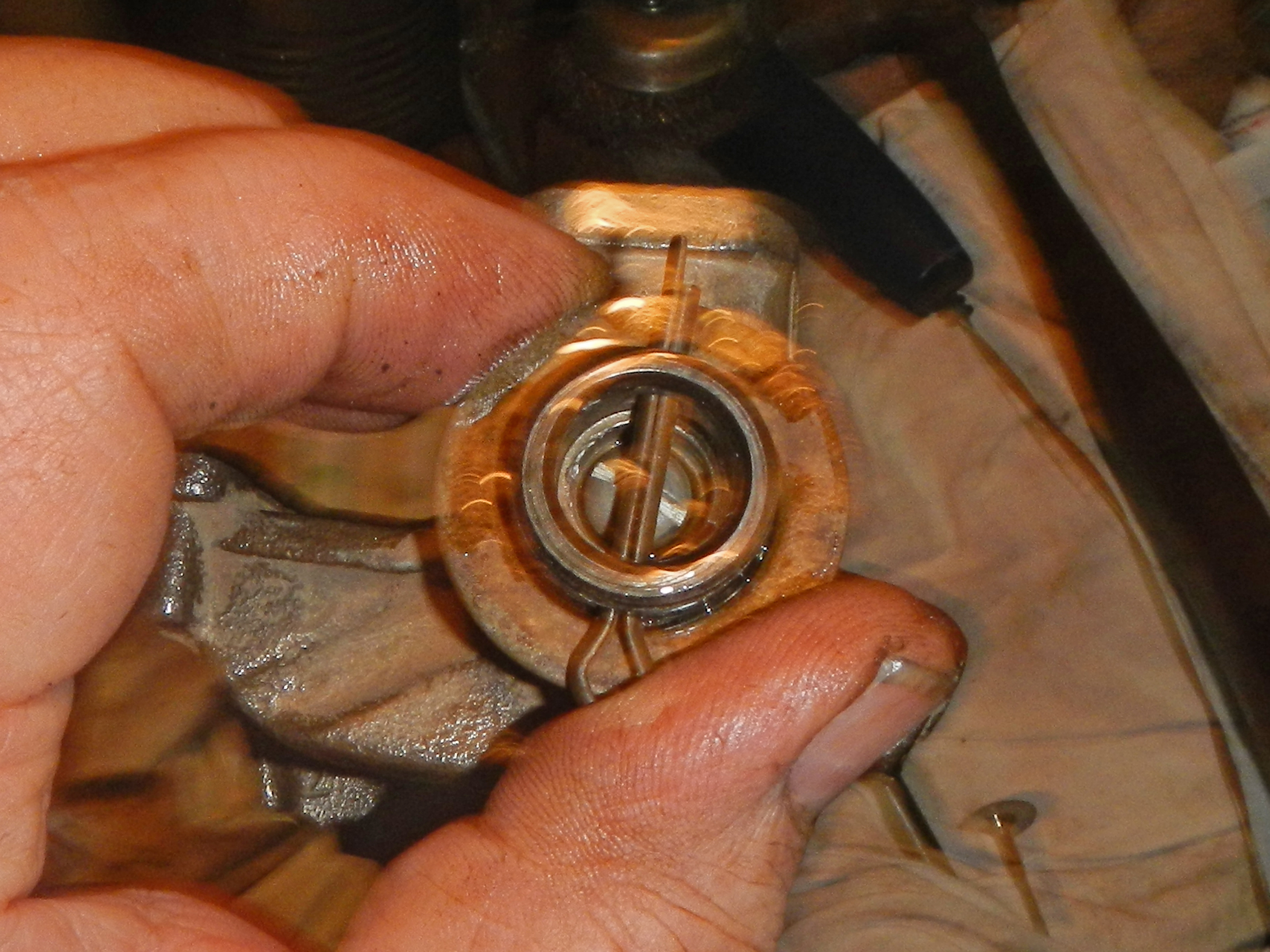

To remove the end plug, I drilled a hole and tapped it for a

#10-32 machine screw. Using a couple

washers and a claw

hammer, I simply pulled the plug straight out. To get the

opposite plug

out, I sent a long rod down the hole and pushed it

out. Save all your parts to be reassembled later.

Warning... The

inside contains dinosaur muck that will get all over you. It

resembles dirty but light grease

that stops oil flow to all

the rocker arms. This goo is nasty.

Please do not use a

bore brush! They always shed bristles that can quickly

ruin your overhaul. Use plenty

of solvent and a 'lintless' rag on a

stick then wash it out very well.

#8

#8

After a good cleaning, hold the shaft up to the light, and look.

ROCKER ARMS

#9

#9

Clean the rocker arms and notice the oil groove inside.

Worn rockers have these grooves 'washed out'.

The groove

directs a small flow of oil from the shaft to the pushrod and

valve tip. Use a drill bit to hand-ream

the two holes, clean.

#10

#10

I use a Dremmel tool with a diamond saw to regroove the rocker arm oil slits. Now they're good as new.

#10a

#10a

Draw your attention to these slots ground into the hardened shafts. They are there because some

rocker arms sit so far off they miss the oil hole on the bottom. This is the counterpart of those rocker

arm grooves. If you buy an aftermarket rocker arm shaft and these slots are missing, get a hand grinder

and put them in.

#11

#11

I plug the tapped hole by leaving the screw all the way in. Knock the plug back

in the hole until it hits the stop.

#12

#12

The round screw head neatly fits just under, but doesn't touch the cotter pin.

#13

#13

Time to reassemble the rocker shafts. Remember,

laying next to each other, both shafts and arms

are identical.

One notch will face the

front on one shaft and the other shaft's notch will face the

rear.

#14

#14

Now that the valve train is ready, BEFORE clamping the

rocker shafts down, it's important to measure

valve-to-piston

clearance.

This is a new setup with different pistons,

valves, lifters and pushrods. There is NO way to calculate

this

measurement beforehand. Notice the #1 spark plug has

an air hose fitting screwed in. I'm about to put

the piston on bottom, pressurize the cylinder and remove the

springs from #1.

Top of Page

or

CLICK HERE

to return to Home Page

#1

#1 #2

#2

#3

#3

#4

#4 #5

#5 #6

#6 #7

#7 #8

#8 #9

#9 #10

#10 #10a

#10a #11

#11 #12

#12 #13

#13 #14

#14