#1

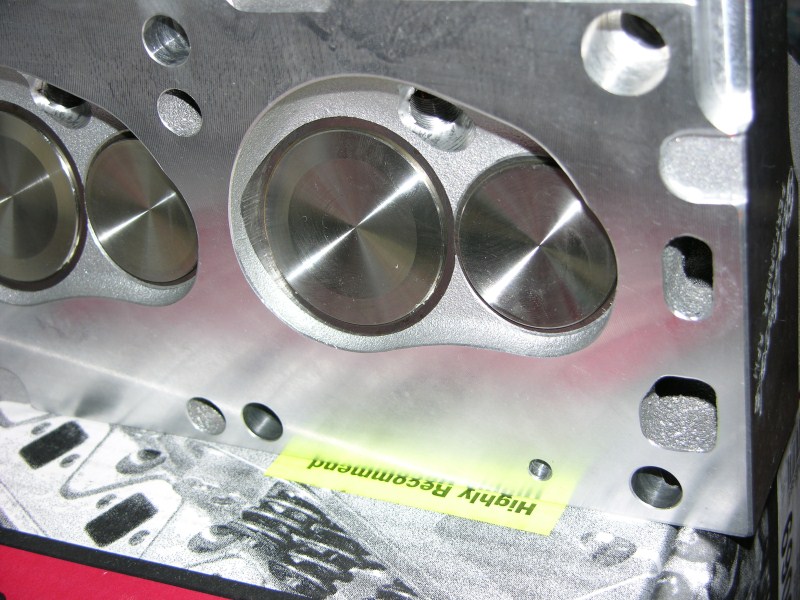

#1Edelbrock has moved the valves to better utilize the space given in the combustion chamber for large valves. For this reason, these heads will only fit bored 390 and 427 blocks. The valves will hit smaller bores.

After the machine shop cleans, Magnafluxes and they determine the castings are good, it's time to order parts. They determine the size of piston needed, then I put an order together.

While the block is

being worked, I order the new parts. Everything else, I reused

from the stock engine.

Clicking on the following headings

will bring you there:

HEADS:

Let's start with Edelbrock FE Performer RPM aluminum heads, already

assembled. Edelbrock part #60069:

#1

#1

Edelbrock

has moved the valves to better utilize the space given in the

combustion chamber for large valves. For this reason, these

heads will only fit bored 390 and 427 blocks. The valves will

hit smaller bores.

Edelbrock leaves a whopping 5/8" of

aluminum on the bottom in case they need to be machined. I am

using them straight out of the box with little modification.

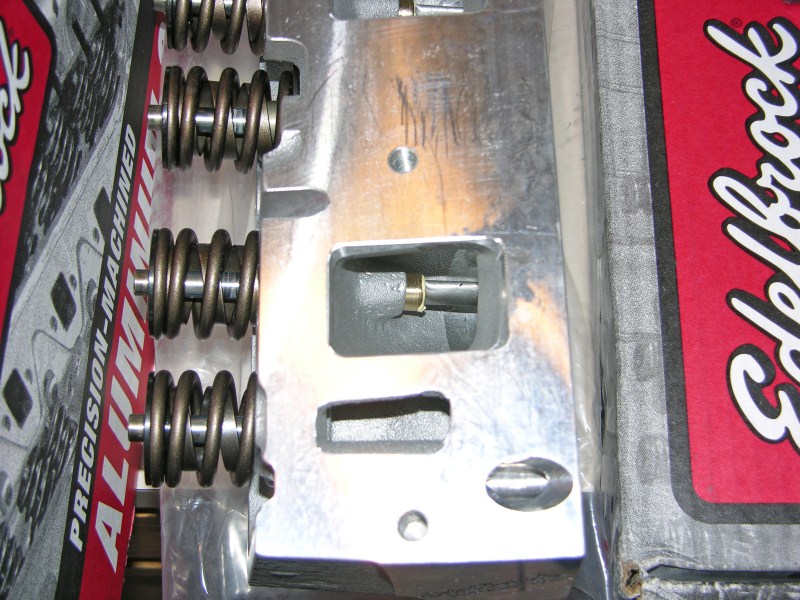

#2

#2

This valve

train will be matched with a Comp Cams hydraulic roller setup, so

the springs need to be correct for the cam.

#3

#3

The valves are stainless steel, seats are cast iron and the entire

head was CNC manufactured for perfect repeatability.

#4

#4

The guides are

silica bronze and the seals are Viton.

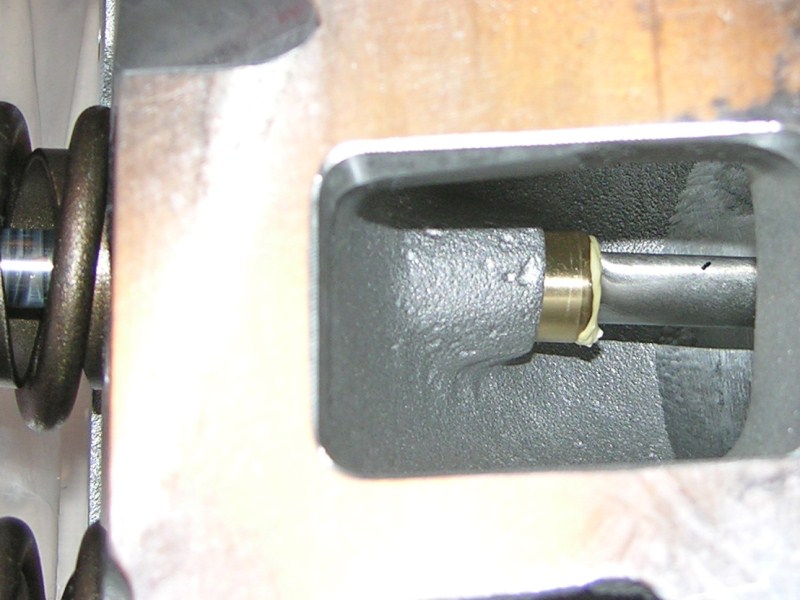

#5

#5

Lubed from the factory and ready to go...

Motor oil travels up the #2 and #4 cam bearing to this short

jog (or trough, at the bottom of the head), to lubricate each entire

rocker arm assembly. They make the trough deep in case the head

is shaved.

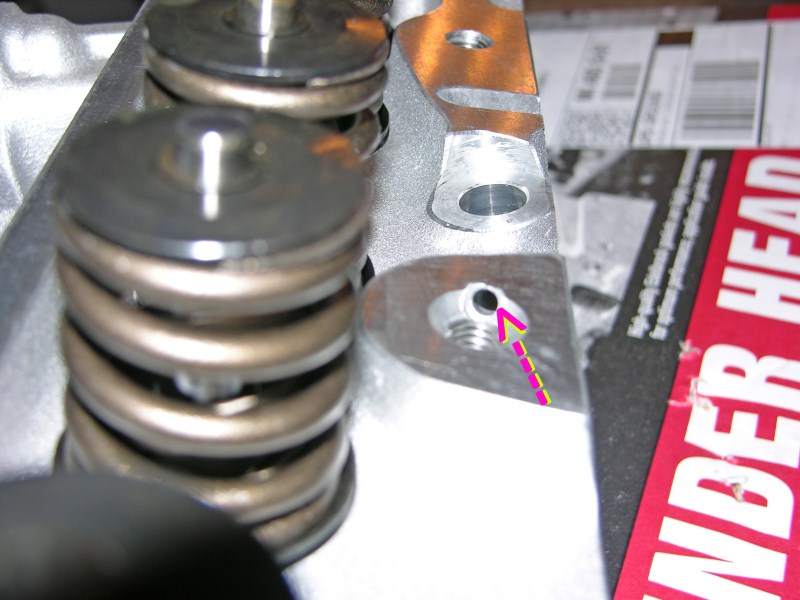

This is the top side of the oil hole. The hole is large

and it passes too much oil.

#8

#8

In the OIL MODIFICATION section, I will tap this hole for

1/4"-20 threads, plug the hole, then drill a smaller hole to

restrict oil flow.

CAMSHAFT & LIFTERS:

#9

#9

I kept the COMP CAM in the bag to keep dirt out. It is a

FE XR270HR-10. Basically that means it has a duration of

210 degrees and it is a Hydraulic Roller cam.

#10

#10

The hydraulic lifters are Morel FE Hydraulic Roller Lifters,

.785" diameter.

#11

#11

They are a lot taller than stock lifters because of the roller

on the end. That means we need custom length pushrods.

PISTONS:

#12

#12

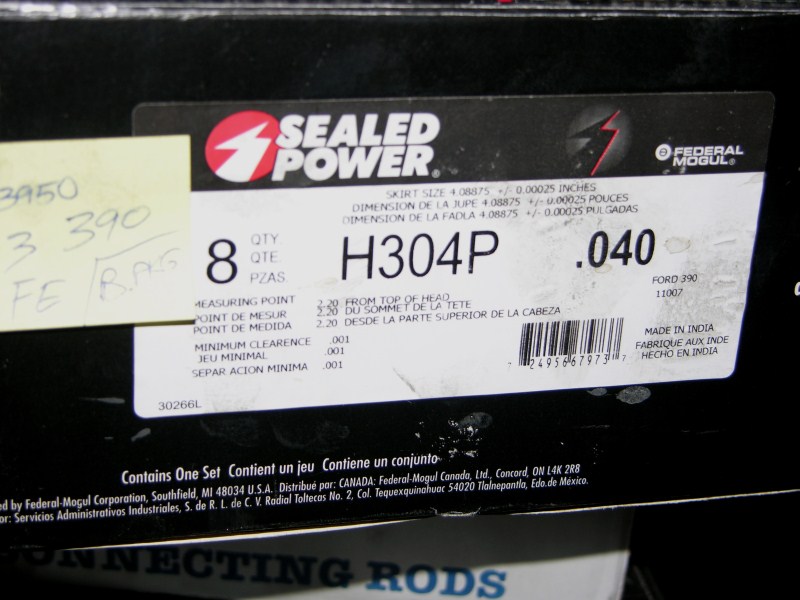

As labled, this is a set of 8 Sealed Power pistons, part #H304P,

oversized .040". The "H" is for hypereutectic alloy.

#13

#13

#14

#14

A closeup of the piston.

GASKET SET:

#15

#15

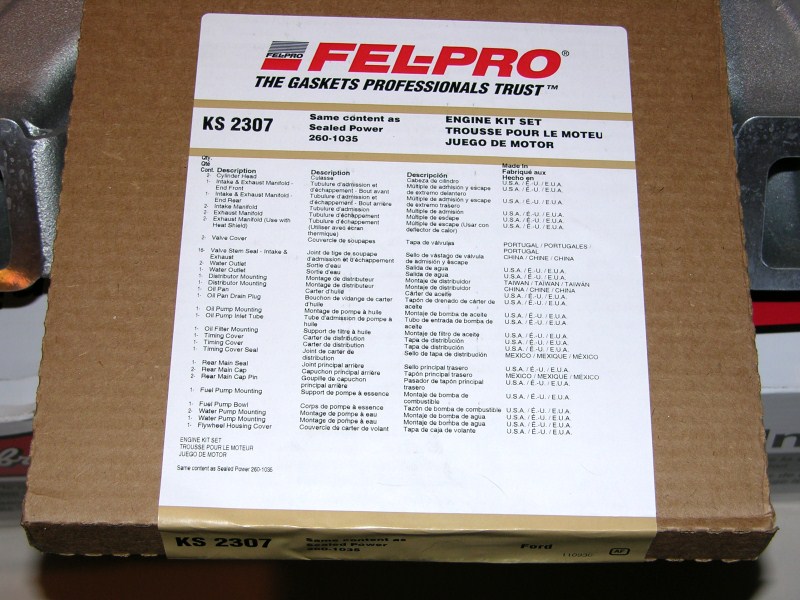

All the parts are important but the Fel-Pro KS 2307 is the ONLY

set I would ever buy for a Ford FE engine. All the

individual gaskets are listed on the label.

#16

#16

I fitted the intake manifold gasket and made sure it was metal

around the water ports. This area is where many builders

fail to get a good intake manifold seal.

BEARINGS:

#17

#17

Sealed Power (again) because it's the best.

Main

bearings are on the LH side #4261 M 10, because the crankshaft

Mains are +.010".

Rod Bearings are on the RH side #8 3230 CP

10, because the 8 Crankshaft Pins are +.010".

OIL PUMP & DRIVESHAFT:

#18

#18

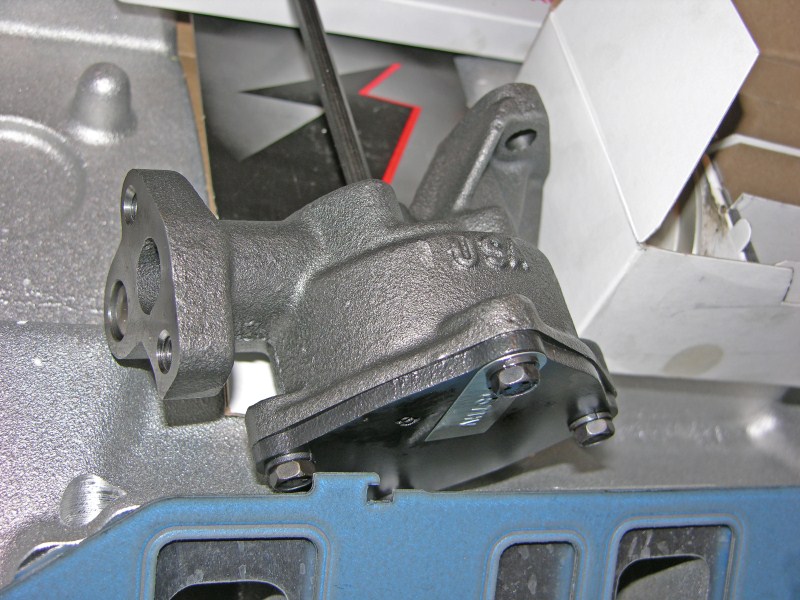

Melling is top quality. The pump is part #M57HV, meaning

it is High Volume, and the driveshaft is part #IS-60, a standard

1/4" FE driveshaft.

#19

#19

The whole thing is very heavy duty and is made in the USA.

Notice the embossed tag on the bottom plate with the part

number.

INTAKE MANIFOLD:

#20

#20

Edelbrock Performer RPM Part #7105, to match the heads.

#21

#21

Notice the 5/8"

coolant bypass nipple is not there. I got one from

my local auto parts store for two bucks, cut it to length and

pounded it in. It was no biggie.

Timing Chain Set

#22

#22

This is a 'True Double Roller' timing set from Summit Racing

Part#G6608. It came in under fifty bucks and it works

great.

Piston Ring

Set

#23

#23

Hastings Moly Ring Set of 8, Part #2M 574 40. '2M'

denotes: Moly Top Compression Rings and Chrome Oil Rings.

The Sealed Power piston ring thickness = 5/64" x 3/32" x

3/16".

Top of Page

CLICK HERE

to return to Home Page