Ford 390 FE Engine Overhaul

1963/ FE CAMSHAFT & TIMING SET ASSEMBLY & SETUP

BACK TO HOME PAGE

#1

#1

Here's the correct assembly setup

for the roller cam I am using. Previous years used the button and spring

instead of a thrust plate (6269). Ford dropped the old setup in

favor of this one. Unfortunately for older engines, parts are

limited and high in cost. Parts for these engines are plentiful

and inexpensive. I suggest if you have an old setup, you can use

this one by drilling two holes and buying the thrust plate for ten

bucks. Then, a wide array of modern cams at decent prices are

available at every speed shop.

At the time of printing,

True Double Roller Timing Sets were not on the market. They last

three times longer than conventional chains and are available at

Summitracing.com for $40.

#2

#2

Verify the bearing

holes are properly lined-up with the block. Use

a good engine assembly lube in each cam bearing. Installing the

cam before the crank is easier because it is open from inside the block.

It's easier to take pictures, too. If your crank is already

installed, you can still install the cam.

#3

#3

Carefully start turning and

fishing the new cam into each bearing.

#4

#4

#5

#5

#6

#6

#7

#7

Everything looks and feels

good.

#8

#8

Notice I use blue

(removable) LocTite on the bolt threads.

#9

#9

This is just a mock-up

because the crank needs to be installed before setting the chain and

sprockets. I'm showing how this will look when finished.

#10

#10

Follow the Shop Manual

instructions for aligning the sprockets with the marks. Don't

forget to LocTite the cam bolt and torque to 45ft/lbs. Notice

the cam bolt washer holds the eccentric and it traps the locating pin from

coming out.

I'm going to kill a few

birds with one stone, here. This is how your new timing set

should look with one exception. I slid the crankshaft sleeve

on backwards (just to hold the slinger in place). Normally at

this point, a garage mechanic would wrap up this job, be done and

get paid.

But wait, how do we

know the marks are correct? What happens if a mark is missing?

How can we double check cam-to-crank timing before bolting the

covers back on? What happens if the marks are WRONG?

CHECK CAM POSITION

AGAINST THE CRANKSHAFT POSITION TO MAKE SURE THE TIMING MARKS ARE

CORRECT.

We need to put the cam

in position where it is at top dead center and see if the crankshaft

agrees. For this, we need no fancy tools, but let's use what

we know.

Let's look at the

firing order. Since this is a four-cycle engine, let's connect the

firing order using two lines:

1 5 4 2

| | | |

6 3 7 8

When #1 is in its power stroke, #6 is in its exhaust

stroke. Both pistons move up & down together. More specifically, half way between when #6 closes

it's exhaust valve and opens it's intake valve, right when these two

lifters are dead even, #1 should be at TDC.

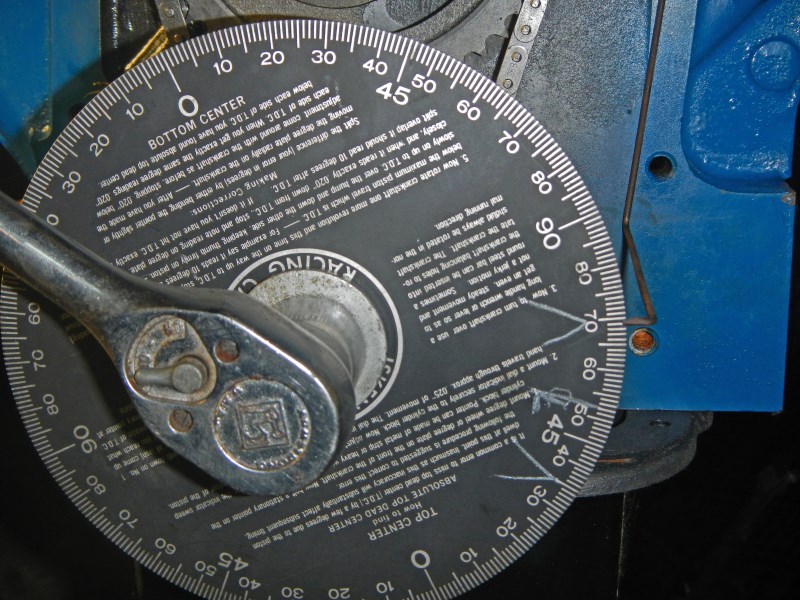

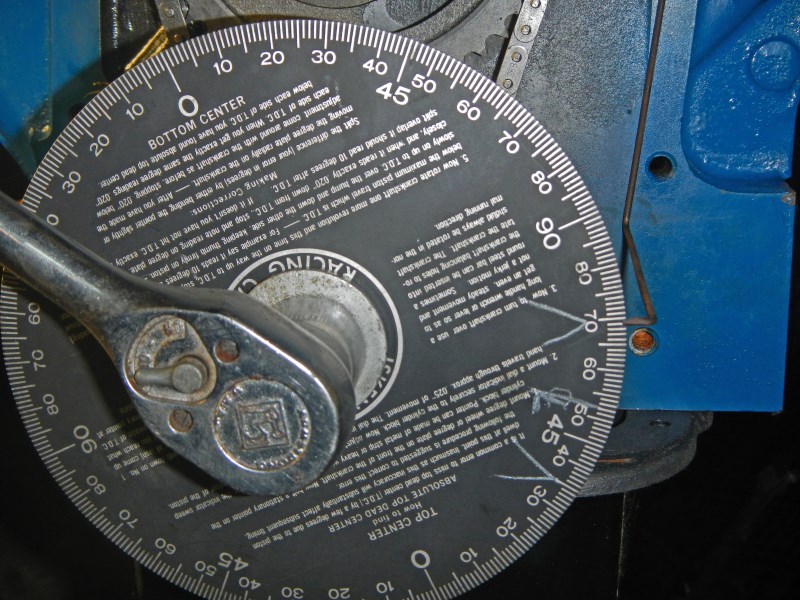

I advanced my cam by just

a small amount. Let's see how the degree wheel verifies this.

Notice I bent and

mounted a coat hanger as a temporary pointer.

I need to find TDC on the crankshaft.

#11

#11

I pulled #1 (or #6)

spark plug and screwed a Piston Stop in the hole. Then I installed my

old trusty degree wheel. It doesn't matter where the wheel

location is,

as long as it's tight on the bolt.

BTW, you can download a

free degree wheel from the net, print it out and glue it to shirt

board.

I ran the crank around

until it stopped. Then I made my first chalk mark on the

degree wheel.

#12

Then, I ran the crankshaft around the opposite direction until it

stopped. Exactly between my marks is my center line or

true TDC. At this point,

remove the Piston Stop

and store it away.

#13

#13

Ok, I rotated the crank until these Morel roller lifters are exactly in between

exhaust and intake strokes as described.

You can use a 'straightedge' at the lifters or at the rocker arms.

For this picture, I'm using a pushrod for a 'straightedge'.

#14

#14

Look where the pointer landed. It's about 5 crank degrees

before my centerline. That means the cam is advanced about

2-1/2 degrees. That's right where I want the cam, advanced

anywhere between two and four degrees. That brings my torque

curve toward low-to-mid range for more power and efficiency at street and cruising

speeds. If this roller chain ever stretches, timing will go toward zero

advance or 'factory setting'.

#15

#15

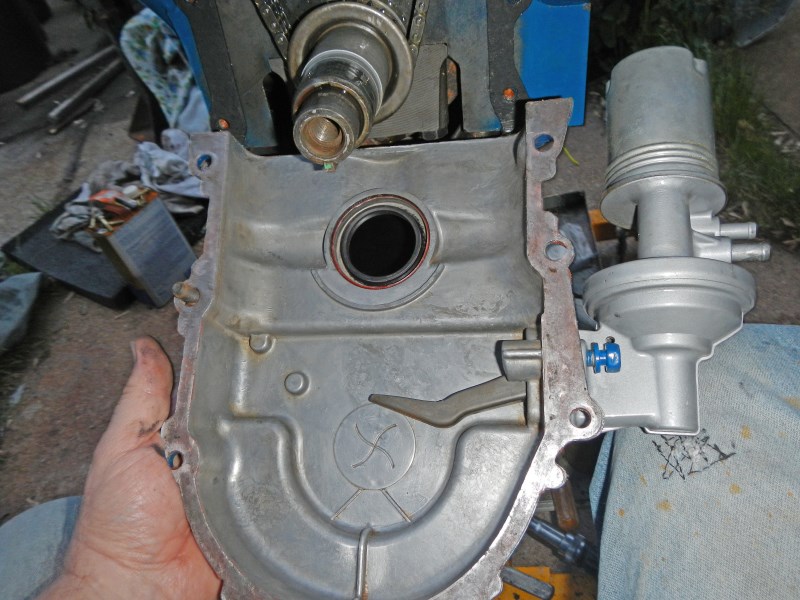

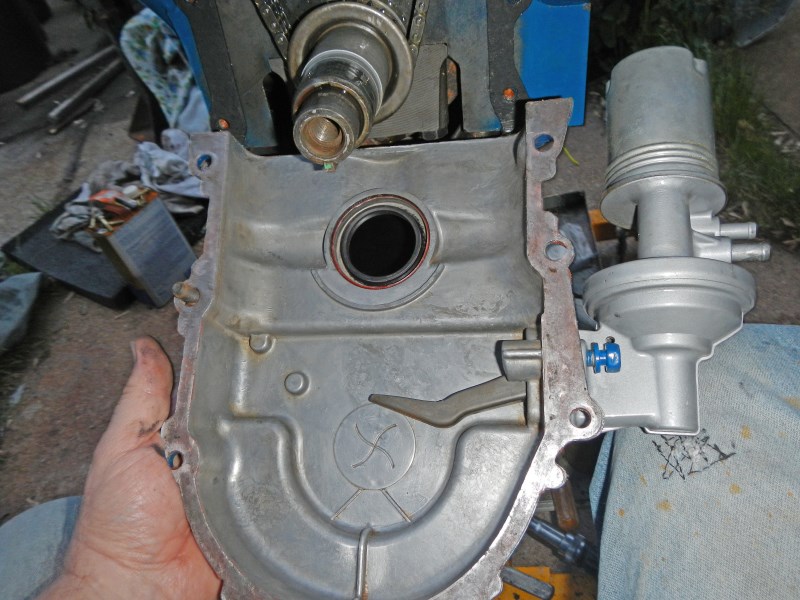

Now that we know it's right, time to pull the crank sleeve off and

install the timing cover.

#16

#16

After the cover is installed, slide the crank sleeve back on and

install the key.

Clean up the pointer for easier timing mark viewing.

#17

In 1973 this F-100 engine was Ford Blue. I'm painting the

block black for Penelope, a beautiful 1960 Thunderbird.

Pictures don't do well when everything is black.

#18

#18

I don't know if this oil pan, timing cover and damper pulley will be

used, or the parts from Penelope's 352.

#19

#19

Tighten all the bolts and she's ready to go

.

Top of

Page

CLICK HERE

to return to Home Page

#2

#2 #1

#1 #3

#3 #4

#4 #5

#5 #6

#6 #7

#7 #8

#8 #9

#9 #10

#10 #11

#11

#13

#13 #14

#14 #15

#15 #16

#16

#18

#18 #19

#19