#1

#1Block assembly starts with the details. Chase all the tapped holes to make sure they are clear, deep enough and the threads feel smooth. Do this for every threaded hole in the casting. Clear the chips out by using a magnet and air.

CLICK HERE

to return to Home Page

The block is machined, main bearing caps are honed, oil

modifications are done and we're ready to assemble.

The crankshaft is balanced, pistons & rods are all matched. I

always start by chasing all the holes, then I install the camshaft

because the crankshaft is not in the way.

#1

#1

Block assembly starts with the details. Chase all the

tapped holes to make sure they are clear, deep enough and the

threads feel smooth. Do this for every threaded hole in

the casting. Clear the chips out by using a magnet and air.

#2

#2

#3

#3

Now, lube the cam

bearings and carefully fish the cam in place, so as not to nick the

bearings.

#4

Clean the journals well, insert the oil seal halves, insert the main

bearing half-shells and carefully lay the crankshaft in place.

#5

After checking bearing clearance on each main bearing using Plastigage, spin

the crank by hand. In fact, I do this along the entire build.

If the crank binds, stop. Go back and find the bind and fix

it. The crankshaft should be true and smooth at every ground

surface. Bearings are extremely soft. A small 'ding' in

the crank will wipe out a bearing or possibly 'spin it' in no time. If you have a

ding in the crank, locate it and carefully stone the ding out and clear all debris before

continuing. If the crank spins freely, proceed with installing the oil seal,

then check it again.

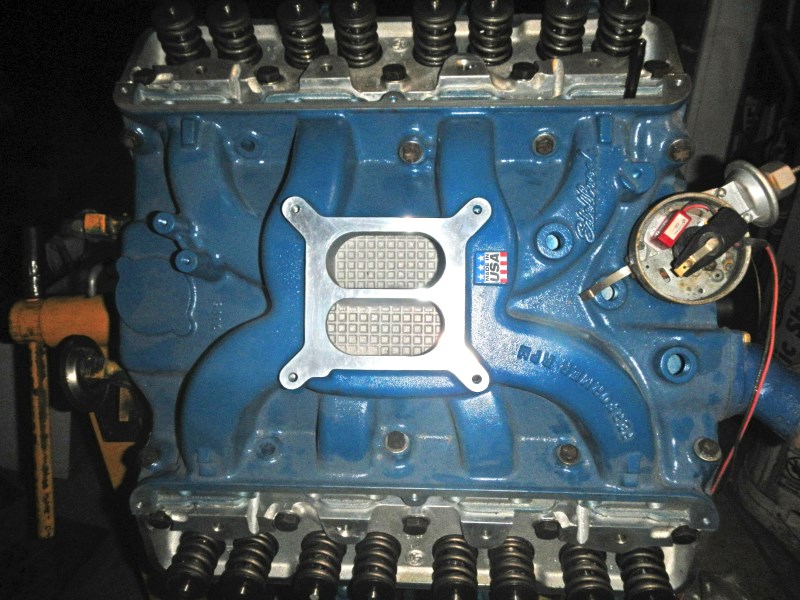

Here is the dual

plane intake with the distributor installed. That is a

Pertronix pickup inside the dizzy.

#6

Notice the black "X" marks. Since we are using +.040"

(heavier and larger) pistons, Mallory Metal was inserted and

welded into the crankshaft counterbalances. Mallory Metal

is half-again as heavy as lead but hard, like carbide steel.

Notice the surface drill holes for dynamic balancing. This

balance job was done right and the result is the best I've ever

seen.#7

All piston rings must be checked in their respective bores for end gap

clearance. <--This is important!

Regardless, if your ring set is "file to fit" or "pre-sized"

doesn't matter a damn. One tight ring can ruin your bore

and/or piston, and will probably break the ring in the piston

groove (rendering it useless). Tight metal must go

somewhere. When I disassembled this

390 I

found one factory ring that was broken. The ring was new when it broke. So for the rest of this

old engine's life, all that ring did was go along for the ride

and promote more blowby. We need ALL rings to seat

properly and work hard for the next 250,000 miles.

These hypereutectic alloy pistons conduct heat faster than

ordinary pistons, so the Moly ring end gaps must be much wider than

1959 pistons. For our bore, we need .022" gap.

Use a bare piston to slide the new ring down the bore so it sits

straight, then measure the gap with a quality feeler gauge.

#8

I use a brass protection sleeve when installing rings. It

allows the ring to open 'just enough' and it keeps the ring ends

from grooving into the piston as it slides down. Twisting

or curling the new ring will bend it. Then the ring will

never seat.

#9

All rings must slide freely in their slots. If one

hangs up, correct the slot.

#10

Now that the ring set is installed, this is the last time to

check. Keep it straight in your head: The notch in the

piston top goes forward, the rod has an offset oiling hole at

the wrist pin that sits on top when the engine is installed, and

each wrist pin has two snap ring keepers. If any of this

isn't true, stop.

#11

There are several good ring compressors and sleeves for

sale. This one happens to be a Lisle. I've used it

for many years.

Piston rings turn, by design. Don't put an awful lot of

emphasis on getting the gaps in a certain orientation.

This constantly changes by itself, the same holds true for

rotating valves.

#12

Insert the bearing and lube all parts of the piston well,

before installing. I brush oil into the oil groove.

To protect from nicking the crankshaft, I use hose material over the cap studs.

The hose must be thin and easy to remove.

#13

Turn the crank so the pin is at the bottom.

This gives room for your hands to grab the rod and guide it as

you gently pound the piston in with a rubber mallet or a wooden

hammer handle.

#14

Here it comes. Work both top and bottom ends

simultaneously to align everything. If the piston needs to

turn a little, grab the ring compressor tool and turn. The

rings won't turn but the piston will, so the rod will align with

the crank.

#15

I also brush a bit of oil into the crank holes before

it is covered.

#16

At this point, get out the plastigage and measure for

clearance. BTW, you start to see oil running down the

crank. I would much rather have too much than too little

oil. Put a pan under the engine because this is going to

get worse.

#17

Yep, right in spec's. Now remove the

plastigage (which is really wax), lube the bearing and torque

the cap.

#18

After tightening, turn the crank by hand. If it feels

good, do the next seven pistons the same way.

#19

All the pistons in the Left Hand bank are properly stuffed,

clearance measured. Time to do the RH side.

#20

I only use a good quality torque wrench and proper torque

procedures.

#21

#21

Now, the camshaft thrust plate is mounted using Loctite on the

original screws.

I drew this imaginary line to show how much I have advanced the

cam. Normally, the dowel pin on the cam sprocket and the

keyway on the crankshaft align straight. After degreeing

the cam, I purposely made the bottom sprocket 1/2 the width of

the key off, to give me 4° of cam advance (or 8° of crankshaft retard). This boosts the low end

torque. It also compensates for any chain stretch when the

engine gets old. This is a double-row, true roller timing

set is designed to last three times longer than the OEM

chain. Notice it's all steel (no nylon).

#22

#22

New Melling high volume oil pump and new Melling driveshaft.

Time to mount them using Loctite on the bolt threads.

The sheet metal 'washer' on top of the driveshaft is to prevent

the distributor from pulling it out of the oil pump.

#23

The rear seal is done, block gasket surface is cleaned with

lacquer thinner and a thin coat of Permatex black is applied all

around the gasket area.

The pickup is squeaky clean and I pulled the screen up, closer

to the bottom. When I first saw it, the screen was sucked

up and very dirty.

The metal tag says, "M57HV" for Melling part number 57, high

volume.

#24

This oil pan had many dents that came out with a little

persuasion. Install the oil pan.

#25

Time to install Fel-Pro head gaskets. Pay close attention to the

word, "FRONT" covering the water hole. In fact, most of

the water holes in the front of the block are either covered or

are very small. The large symmetrical holes (between

cylinders) are for head bolts, the two medium size on top are

for oil and the tiny (and bottom medium size between cylinders)

are water passages. Ford engineers went through extensive

tests to get an even cooling. They want coolant to flow passed the

iron cylinders, and continue toward the rear of the block, then

come up through the head gasket and out the heads and intake

manifold.

#26

Here is the same gasket, showing back cylinders (#4, 3 & 2).

Notice the rear water hole is open wide.

Both sides are identical. Go ahead and mount the heads on

these properly oriented gaskets.

BTW, if gaskets are not oriented correctly, the rear cylinders

will quickly overheat and possibly ruin the job.

#27

CAUTION: When using steel bolts with aluminum, ALWAYS use

hardened washers.

I tighten FE head bolts after the intake is in place, just to

ensure a good seal with reduced intake gasket 'walking'.

Notice I used the original long head bolts but I bought new

short bolts, that are exposed outside the head.

#28

#28

Before installing all the lifters, make sure all the oil gallery

plugs are in place and are seated correctly.

This is an FE, and these details are often missed by mechanics

who aren't familiar.

#29

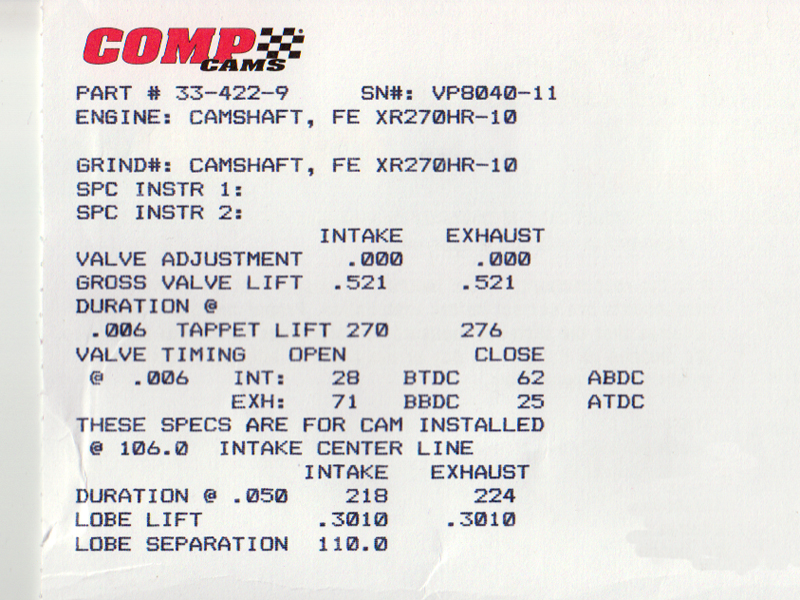

These are properly oriented Morel hydraulic roller lifters that

mate with the Comp Cams FE XR270HR: #30

#30

#31

#31

Many restorers omit the valley baffle plate. I see no harm

in keeping it. Notice the intake manifold gaskets are in

place with Permatex black only around the water ports (on both

sides of the gasket.

#32

#32

The intake manifold eliminates exhaust crossover, and sends the

hot exhaust out each exhaust manifold.

Sealing this manifold has caused many restorers fits because as

the bolts are tightened, the whole manifold slides down under

the bolt heads. Sometimes this causes the gasket to

'squirm' and leak at the coolant ports. Therefore, I take

two precautions: I don't put gaskets on the front or rear

of the block (where the intake manifold mates). Instead, I

fill the area with Permatex after the intake has settled all the

way down. AND, after the intake manifold bolts are

slightly tight, I then torque the head bolts.

#33

#33

This is the earliest opportunity to install pushrods because

they go through the intake manifold. The problem with this

is, we don't know what length the pushrods shoud be since the

lifters are a lot higher than stock lifters, the cam is

different, the cam timing is different, etc., etc., ... We

need to install rocker arm shafts, measure for pushrod length

and check valve-to-piston clearance. Notice I have one

pushrod sticking up for #5 cylinder.

#34

#34

The intake manifold doesn't come with the 5/8" diameter water

pump bypass nipple. I cut this one and pounded it in,

leaving 1-1/4" sticking out for the 5/8" rubber water pump hose.

Also notice, the timing chain cover is installed along with the

fuel pump and oil filter adapter.

#35

#35

These fittings were swapped from the old manifold. The

small brass fitting is the temp gauge sending unit. The

ell is the supply for the heater. The open threaded hole

is for vacuum (power brake booster, ignition advance and PCV

valve).

#36

#36

Here is the new fuel filter.

Top of Page

CLICK HERE

to return to Home Page