Ford Instrument Cluster Voltage Regulator Assembly

Solid State Retrofit

TRIM - Dashboard Section

The original Instrument Cluster Voltage Regulator has been called by

many names including, Constant Voltage Regulator or simply, CVR.

Ford's last year for six-volt systems was in 1955, and the Dashboard

had no CVR. In 1956, Ford went to 12-volts. This was the

only year the instruments were 12-volts and again, no CVR. In

'57, Ford quickly went back to using six volts for all the gauges,

corporate wide, and they remain as such today.

The OEM CVR works much the same as a turn signal flasher with three

leads: One goes to Ignition power, one lead to ground, and the other

to the gauges. So the original pulled 12-volts through a

resistance wire that was wrapped around a bi-metal strip, to ground.

As the bi-metal strip got hot, the normally closed contact would

open, then cool and close, over and over as long as the key was

turned on.

The assembly comes with an adjustment screw (that is painted), but

none of the manuals explain how to adjust the timing. A 6-volt

average of 12-volts would be an on and off time of 50%, or 50% duty

cycle. I put my Fluke meter on one and checked for Hz.

It was all over the map, from 0.4-seconds to 1.4" and very irratic.

I realize this was a cheap way to get 6-volts back in the day.

Now we have much better methods.

For the scope of this site I will retrofit a 6-volt Solid State

regulator into the original metal case, showing each step.

Then I will test it.

#1

#1

This is the location and part numbers for Squarebird CVRs.

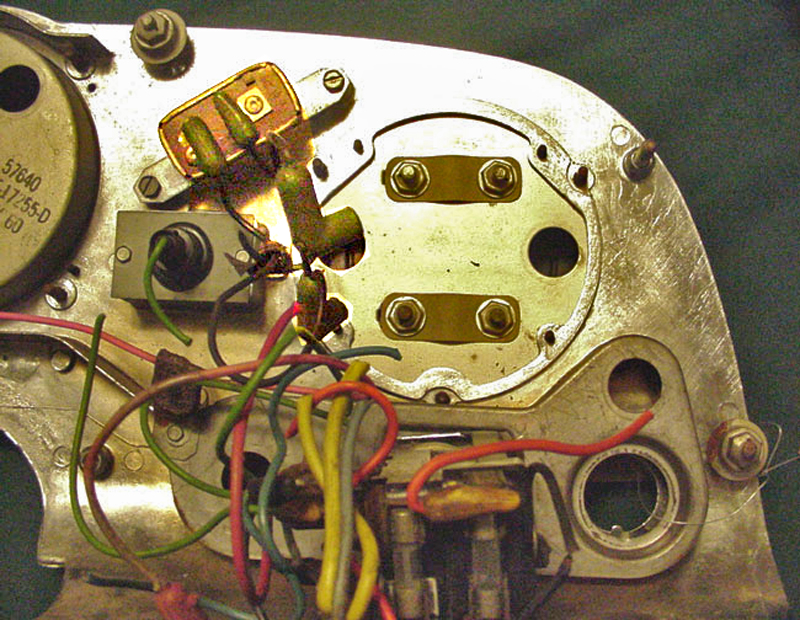

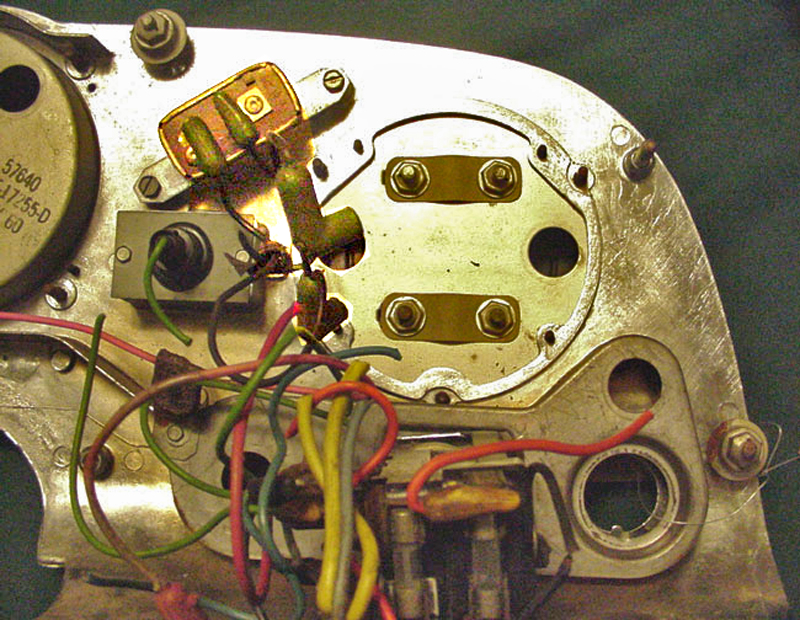

#2

#2

These are two broken units, removed from different Squarebirds.

#3

#3

The first job is to open the case.

#4

#4

I'm working on opening the third side.

#5

#5

That's it. Let's see the inside...

#6

#6

The bi-metal strip on the right side is wrapped with very

small resistance wire which causes it to heat. This one is

burned open. Notice the end of the tiny wire goes under an

edge clip for the ground connection.

#7

#7

Notice the 'adjustment' jack screw and the grounding clip.

This is a recipe for disaster.

#8

#8

One last look before I tear into it.

#9

#9

The original connectors are tight in the rivets.

Notice I left a stub of metal after tearing the arms off. I

will tin these and solder my 12-v 'Input' and 6-v 'Output' wires to

them.

#10

#10

I removed the adjustment screw. This is a perfect hole to

put a green LED to show the 6-v side works.

#11

#11

All holes I drill will be 1/8".

#12

#12

The solder I use (AQUABOND by KESTER) contains NO lead and is

Silver Bearing. Yeah, it's the good stuff.

I am creating a flat, smooth 'bed' at the bottom of this stamping

(for the regulator). They projection spot welded the bottom

strap to the case, leaving dimples in the surface.

Time to talk about the Electronics...

#13

#13

This is a Fixed Output, LM7806 Voltage Regulator in a TO-220

case. The center leg (2) is also electrically connected to the

metal backing with the mounting hole. So conveniently, the

case will be our NEG.

All I need is two capacitors (C1

= 0.47uF)

and a very small LED with a dropping resistor (150-ohms). I am using the

correct 0.1uF for C0,

but a larger cap for C1

because car electrical systems are notorious for voltage spikes

and drops.

#14

#14

To prevent metal fatigue, it's important to hold the leads with

pliers, away from the case, while bending the leads. If

disaster strikes and the leg comes off, a 'tab' will remain for an

acceptable solder connection.

#15

#15

Place the TO-220 in the housing and mark the 1/8" hole.

#16

#16

These are the setup parts: A 1/8" pop rivet, a 1/8" hole brass washer, and

heatsink compound. Now I am ready to wire.

WIRING

#17

#17

Solder three short leads onto the regulator. It's hard to

see but I marked the power leads, red (12-v) and black(6-v).

#18

#18

Use plenty of heatsink grease and pop rivet the parts together.

Set it aside for later.

#19

#19

I used epoxy to mount the LED. After it cured I added a

dropping resistor (150-ohms@1/8-watt), heat shrink-ed the 6-volt leg

and soldered it to the output post. Notice the NEG leg is

sticking up.

#20

#20

I added the 0.1Uf

capacitor to the same output tab. Now I have two NEG legs

sticking up.

#21

#21

The (0.47uF@50v) Input cap neatly nestles in the middle. See how all

three NEG legs stick up together?

#22

#22

Time to solder all the NEG leads together, then solder the power

leads to their tabs. The next one I assemble will have shorter

wires, but notice that half of the 'can' is empty. That is the

portion where the bulky parts fit into.

#23

#23

#24

#24

I used a wide chisel to hem the edges.

TESTING

#25

#25

Here it is... 12.56-volts from a car battery (IN), and a solid

6.00-volts (OUT).

#26

#26

The indicating LED looks like it belongs there.

#27

#27

I want to extend a special "THANKS" to Yellowrose (Ray Clark) and NYsquarebird58 (Marcelo Laviano) for sending me

their old CVR units. Without them, I was stuck with the electronics in a breadboard,

but no real way to test it. Now, we can save our Squarebird.org members at least US$25

over retail price.

RETURN to TOP of PAGE

#1

#1 #2

#2 #3

#3 #4

#4 #5

#5 #6

#6 #7

#7 #8

#8 #9

#9 #10

#10 #11

#11 #12

#12 #13

#13 #14

#14 #15

#15 #16

#16 #17

#17 #18

#18 #19

#19 #20

#20 #21

#21 #22

#22 #23

#23 #24

#24 #25

#25 #26

#26 #27

#27