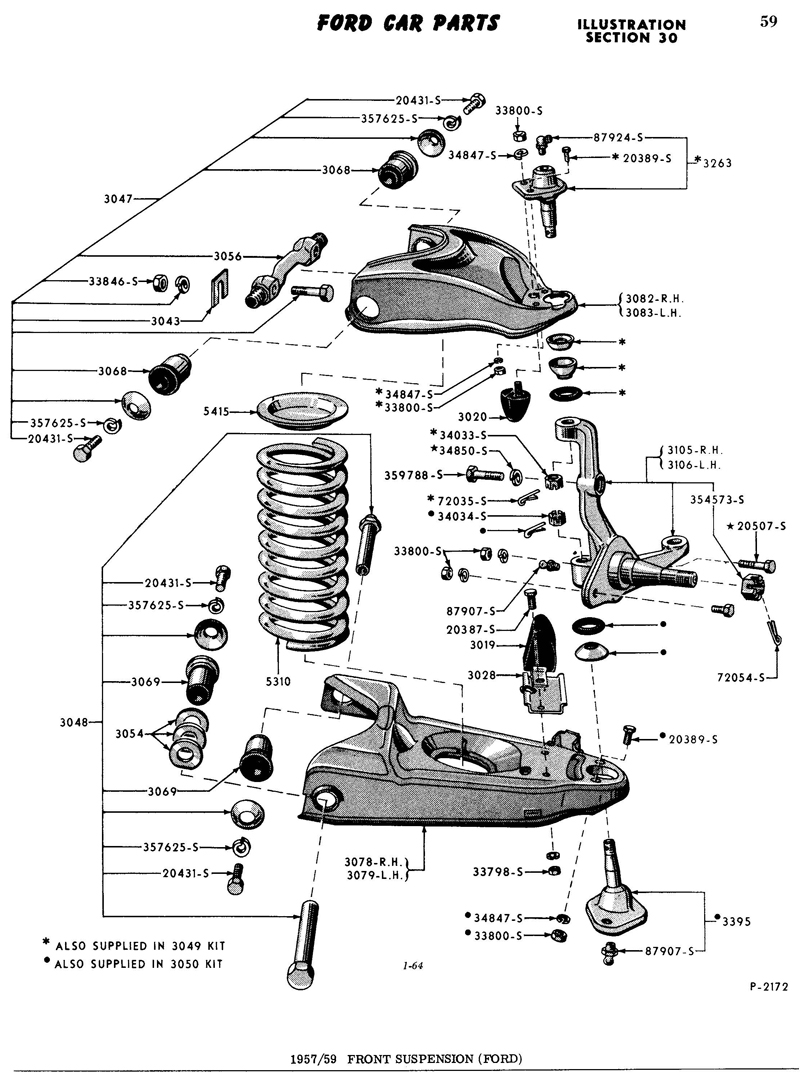

local shop did a ftr end rebuild for me. Now i canot get my pos caster set. Are there shims that go ,on the rear lower control arm bushing? If I can move the lower arm forward with arm rear bushing shim ,then the pos caster can be set. The book specs that the 2 top alinment shim locations should not be mord than XXX differnt. can some one post or send me a pick of the location for the lower arn bushing shims ? any views of the lower arm /bolts/bushings/shims /ect would be great. I want to move the lower control arm forward to increase pos caster. Less shims in frt and more on rear + more pos caster. top ball joint back-bottom ball joint forward =pos caster.

Learned my lesson next time take pics and stamp parts

thanks

Learned my lesson next time take pics and stamp parts

thanks

Comment