Have an exhaust leak on my replacement engine on my Tbird.

Long story short - I found a rebuilt engine cheaper than I could rebuild my original so decided to run it.

Used original 1960 / 352 Tbird manifolds on the new engine because they have the flat exhaust connections - didn't need a new exhaust and for those not familiar with the Tbird specific manifolds they have an indention on the driver side rear to add more clearance to the steering box.

The replacement engine has C4AE-G heads.

My question is - do all FE heads have the same size exhaust ports and are they the same distance apart? Specifically will the '60 manifolds fit the '64 heads without leaking?

I realize that originally the Tbird did not have exhaust gaskets and I was tempted not to put them back but every other car I've worked on had gaskets - MG's to Model A's and I've never had problems.

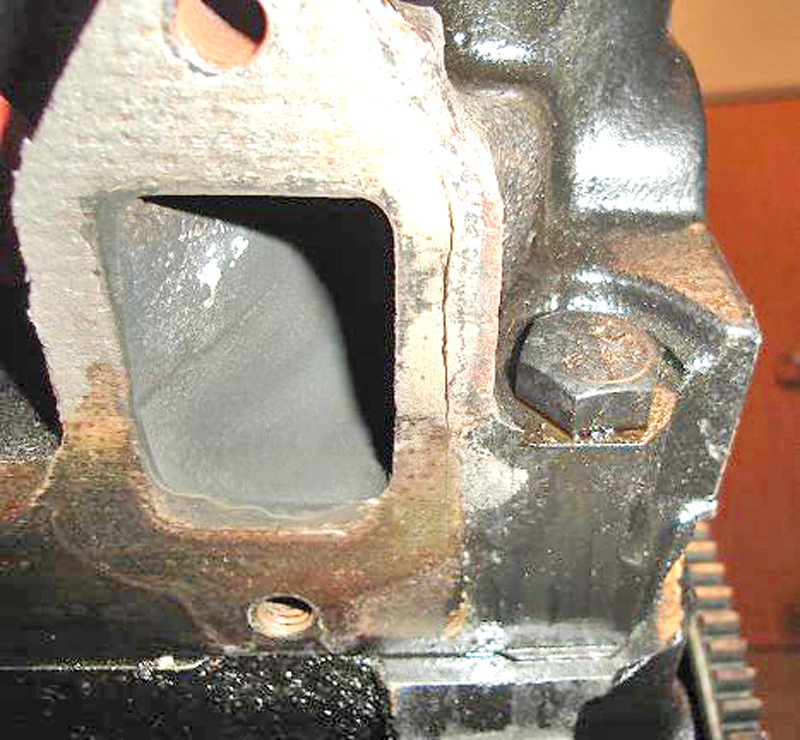

It's leaking at the back of the manifold closest to the firewall. Take a look at the pic below - it almost looks as if the manifold is not long enough to cover the rear exhaust port. Caught it rather quick so not much exhaust residue to show the leak. The passenger side however is working fine.

Plan to remove the manifold and have it surfaced then re-install with gaskets. I did not have the manifold surfaced the first time but checked it with a steel straight edge and it "looked" fine.

Info, ideas and opinions appreciated.....

Eric

Sure is easy to pull the fan and water pump with the hood gone.

Ok - the manifold....

Oh - new bolts and washers - just took the pic after I had bent the tabs up to start the removal process. Also used permatex copper coat when installing the new gaskets and used manifolds. This is after about 1000 miles.

Long story short - I found a rebuilt engine cheaper than I could rebuild my original so decided to run it.

Used original 1960 / 352 Tbird manifolds on the new engine because they have the flat exhaust connections - didn't need a new exhaust and for those not familiar with the Tbird specific manifolds they have an indention on the driver side rear to add more clearance to the steering box.

The replacement engine has C4AE-G heads.

My question is - do all FE heads have the same size exhaust ports and are they the same distance apart? Specifically will the '60 manifolds fit the '64 heads without leaking?

I realize that originally the Tbird did not have exhaust gaskets and I was tempted not to put them back but every other car I've worked on had gaskets - MG's to Model A's and I've never had problems.

It's leaking at the back of the manifold closest to the firewall. Take a look at the pic below - it almost looks as if the manifold is not long enough to cover the rear exhaust port. Caught it rather quick so not much exhaust residue to show the leak. The passenger side however is working fine.

Plan to remove the manifold and have it surfaced then re-install with gaskets. I did not have the manifold surfaced the first time but checked it with a steel straight edge and it "looked" fine.

Info, ideas and opinions appreciated.....

Eric

Sure is easy to pull the fan and water pump with the hood gone.

Ok - the manifold....

Oh - new bolts and washers - just took the pic after I had bent the tabs up to start the removal process. Also used permatex copper coat when installing the new gaskets and used manifolds. This is after about 1000 miles.

Went ahead and drilled it out and welded it. Probably won't last. If I do this again I'm getting a set of headers - PERIOD - tired of the cast manifolds.

Went ahead and drilled it out and welded it. Probably won't last. If I do this again I'm getting a set of headers - PERIOD - tired of the cast manifolds.

. Lucky it was just a brass button on my jeans and will wax out.

. Lucky it was just a brass button on my jeans and will wax out.

(the kit years ago already had the seals on new shafts - just swapped them out - easy). I finally decided to drill a small hole in what was left of the top of the original shaft and hold the seal and washer in with a cotter pin with loctite (topped off with JB Weld) rather than try and re-brad with the small amount of metal that was left. Still not really convinced it will last. The kit seemed to be good quality though otherwise.

(the kit years ago already had the seals on new shafts - just swapped them out - easy). I finally decided to drill a small hole in what was left of the top of the original shaft and hold the seal and washer in with a cotter pin with loctite (topped off with JB Weld) rather than try and re-brad with the small amount of metal that was left. Still not really convinced it will last. The kit seemed to be good quality though otherwise.

Comment