From this thread here

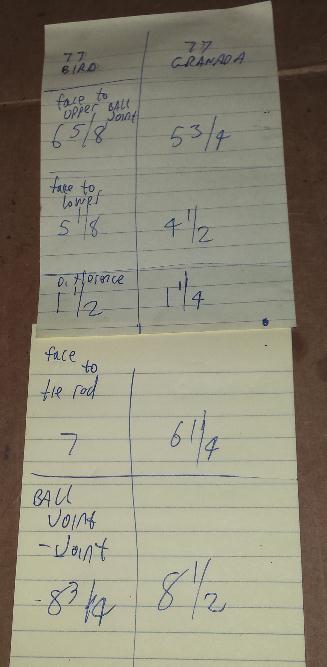

It would appear I have the 77 Bird spindles/brakes.

What is odd is that setup was on the 60 I got for parts,

and that car saw upwards of 6K miles when it was

all together. It did not appear to have severe

camber problems when I picked it up and tire

wear sure does not appear to be heavy on the

positive camber.

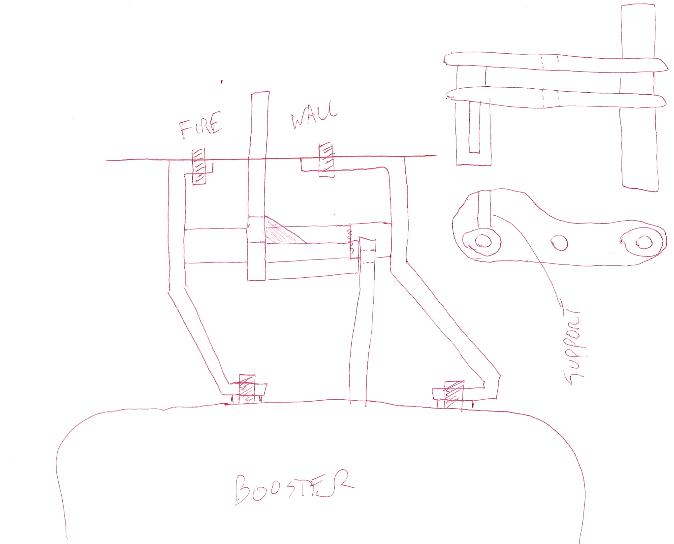

That car did have some kind of aftermarket spring,

so I'm wondering if a lowered ride height pushed the

lower control arm more flat and outward. Couldn't of

been that low as he had a 235 width, 15" tire on them

and no clearance problems.

So now I'm not sure how I want to proceed. I sand blasted

all the parts, but hate to start powder coating if I can't

use this stuff. I would stuff all the parts back on the

parts car with out the springs, but I already removed

upper control arm bushings.

It would appear I have the 77 Bird spindles/brakes.

What is odd is that setup was on the 60 I got for parts,

and that car saw upwards of 6K miles when it was

all together. It did not appear to have severe

camber problems when I picked it up and tire

wear sure does not appear to be heavy on the

positive camber.

That car did have some kind of aftermarket spring,

so I'm wondering if a lowered ride height pushed the

lower control arm more flat and outward. Couldn't of

been that low as he had a 235 width, 15" tire on them

and no clearance problems.

So now I'm not sure how I want to proceed. I sand blasted

all the parts, but hate to start powder coating if I can't

use this stuff. I would stuff all the parts back on the

parts car with out the springs, but I already removed

upper control arm bushings.

).

).

Comment